Triple vs Double Pane Windows in Edmonton

What Actually Fails at −30 °C and When Triple Pane Is Worth It

Short answer

:

Triple pane windows are worth it in Edmonton only for older or air-leaky homes exposed to long-duration cold and wind pressure.

In newer, well-sealed homes, high-quality double pane windows usually deliver similar comfort with better cost-to-benefit, even in extreme cold.

Why This Question Matters for Edmonton Homeowners

Edmonton homeowners are not asking this question out of curiosity. They are asking because replacing windows is one of the most expensive upgrades a household can make, and winter discomfort is not theoretical here — it is lived reality.

The typical decision pressure looks like this:

- Heating bills remain high despite insulation upgrades

- Rooms near windows feel cold even when the furnace runs constantly

- Contractors recommend triple pane as the “cold-climate solution”

- The cost difference feels significant, but unclear in payoff

What often goes wrong is that homeowners assume colder climate automatically means more glass equals better performance. This assumption ignores where heat actually escapes in Edmonton homes and why some upgrades fail to improve comfort even after installation.

The real risk is not choosing double pane instead of triple pane.

The real risk is over-investing in glass while ignoring air leakage, wall performance, and installation constraints.

This article exists to prevent that mistake.

Edmonton Climate Context — Why Cold Here Behaves Differently

Canada does not have a single winter profile, and Edmonton does not behave like other major cities that are Canadіans often compare it to.

Long-Duration Cold vs Short Cold Cycles

Edmonton experiences:

- Fewer Chinook warming events than Calgary

- Longer uninterrupted cold stretches

- Extended periods below −20 °C

- Repeated exposure to −30 °C and colder during severe winters

This matters because materials do not fail from a single cold night. They fail from sustained thermal stress.

Pressure, Wind, and Exposure

Many Edmonton neighbourhoods are more exposed than people realize:

- Wide road corridors

- Flat topography

- Limited shielding between structures

Wind increases pressure differentials across window assemblies. At −30 °C, even minor air leaks become dominant sources of heat loss.

Freeze Stress, Not Just Temperature

Deep cold creates:

- Frame contraction

- Seal stiffening

- Spacer stress

- Increased condensation risk

These effects accumulate over weeks, not hours. Window systems that perform adequately in milder climates can degrade faster under Edmonton’s conditions.

Housing Era Matters More Than Weather Alone

How a home responds to cold depends on when it was built:

- Pre-1980 homes: limited air barriers, inconsistent insulation

- 1980s–1990s homes: improved insulation, but frequent leakage at openings

- Post-2000 homes: better envelope continuity, tighter assemblies

The colder the climate, the more construction era determines outcome.

Long-Duration Cold vs Design Cold (Why Edmonton Is a Special Case)

Most window systems are engineered around “design cold” temperatures, meaning a short-term minimum expected in a region. Edmonton’s challenge is different: cold is not brief here, it is sustained.

Extended periods of −20 °C to −30 °C create a cumulative stress effect on window assemblies. Materials do not simply contract once and recover. Instead, they remain in a contracted state for weeks, sometimes months, which alters how seals, spacers, and frames behave over time.

This distinction explains why some windows that technically meet cold-climate ratings still underperform in Edmonton homes. Ratings are typically based on short test cycles, while Edmonton exposes windows to continuous thermal compression, limiting material rebound and accelerating fatigue.

In practical terms, long-duration cold:

- reduces gasket elasticity more aggressively

- increases the likelihood of micro-gaps forming

- shifts pressure balance toward infiltration dominance

This is why Edmonton homeowners often report comfort loss even when outside temperatures are not at their coldest. The window system is already stressed before the coldest nights arrive.

How Window Performance Actually Works (No Marketing Logic)

Window performance in Edmonton is governed by four interacting mechanisms. Glass configuration is only one of them.

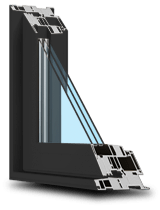

Heat Transfer Through Glass

Adding panes reduces conductive heat loss:

- Double pane creates two insulating layers

- Triple pane adds a third, increasing resistance

However, diminishing returns apply. The third pane reduces heat loss less dramatically than the second did.

Air Leakage Dominates Comfort Loss

In real Edmonton homes, the largest heat losses around windows come from:

- Gasket shrinkage in deep cold

- Poorly sealed frame-to-wall joints

- Retrofit inserts leaving original leakage paths intact

At −30 °C, moving air removes heat faster than conductive loss through glass.

If air leakage exists, pane count becomes secondary.

Frame and Spacer Behavior in Extreme Cold

Materials behave differently under sustained cold:

- Vinyl stiffens and contracts

- Aluminum spacers conduct cold inward

- Seals lose elasticity

Triple pane units increase glass mass and stress on spacers. If the spacer system is not designed for cold flexibility, long-term performance can degrade faster than expected.

Condensation as a Diagnostic Signal

Condensation patterns reveal failure modes:

- Center-of-glass condensation → surface temperature issue

- Edge condensation → spacer or seal weakness

- Perimeter condensation → air leakage

Triple pane glass can reduce center-of-glass condensation, but cannot compensate for perimeter leakage.

Why Air Leakage Overwhelms Glass Performance at −30 °C

At extreme temperatures, heat loss is dominated not by conduction through glass, but by convective heat transfer caused by air movement. Even small infiltration paths can move more heat out of a room than several square feet of glass loss.

At −30 °C, incoming air does not simply cool a surface; it actively strips heat from interior materials. This creates a perception of “cold radiation,” even when the glass itself performs well on paper.

This is why Edmonton homeowners often feel cold near new windows despite high-performance glazing. The glass may be insulating effectively, but the assembly is still leaking air.

Triple pane glass reduces conductive loss, but it does not reduce infiltration unless:

- the frame maintains compression

- seals remain elastic

- installation integrates with the air barrier

Without these conditions, the additional pane becomes a marginal improvement layered over a dominant failure mechanism.

Condensation Physics — Why It Appears Where It Does

Condensation is often misunderstood as a glass problem. In reality, it is a temperature and humidity interaction.

Condensation forms when interior air contacts a surface below its dew point. In Edmonton homes during winter, this most often occurs:

- near window edges

- at frame corners

- along poorly sealed perimeters

Triple pane glass can raise center-of-glass temperature, reducing condensation in the middle of the pane. However, it has limited effect on edge temperatures if spacers or seals conduct cold inward.

This is why condensation patterns are diagnostic:

- center condensation suggests glass performance limits

- edge condensation suggests spacer or seal weakness

- perimeter condensation suggests air leakage

Understanding this distinction prevents misattributing condensation issues to pane count alone.

What Actually Fails at −30 °C and Below

Most window failures in Edmonton are not dramatic breakages. They are gradual losses in performance.

Seal Shrinkage and Loss of Elasticity

At extreme cold:

- Rubber seals harden

- Micro-gaps form

- Airtightness decreases

These gaps may be imperceptible visually but measurable in comfort loss.

Spacer Stress and Thermal Bridging

Spacers experience:

- Differential contraction between glass and frame

- Increased thermal bridging at edges

This often explains why condensation appears near edges even in newer windows.

Frame Contraction and Alignment Issues

Frames contract under cold:

- Sashes may not seat perfectly

- Locking mechanisms lose compression

- Small alignment shifts increase leakage

Triple pane units place greater stress on frame geometry.

Installation-Related Failures

Common retrofit issues include:

- Foam that shrinks in cold

- Missing interior air seals

- Exterior sealing focused on water, not air

Installation failures often appear 5–10 years after replacement, not immediately.

Failure Progression Timeline (What Changes Over 1–10 Years)

Window failure in Edmonton is rarely immediate. It follows a predictable progression.

Years 1–2

:

Performance appears stable. Minor seal stiffness may occur during extreme cold, but rebound happens during warmer periods.

Years 3–5

:

Elasticity loss becomes noticeable. Micro-gaps form under pressure, leading to intermittent drafts during windy conditions. Condensation may begin appearing at corners.

Years 6–10

:

Alignment issues and spacer fatigue become more pronounced. Airtightness degrades measurably. Homeowners often attribute these changes to “aging” rather than specific failure modes.

Triple pane systems, because of their greater mass and reliance on seal integrity, can experience sharper performance drops if components are not designed for long-duration cold.

When Triple Pane Windows Make Sense in Edmonton

Triple pane windows are not inherently wrong. They are context-dependent.

House Conditions That Support Triple Pane

Triple pane tends to work when:

- The home was built before modern air-barrier standards

- Walls have limited insulation depth

- Window openings represent a large portion of exterior walls

Cause → effect

:

Weaker wall systems increase reliance on window surface temperature.

Regional Exposure Factors

Triple pane makes more sense when:

- The home is exposed to sustained wind

- Cold persists for long uninterrupted periods

- There is limited solar gain during winter

Cause → effect

:

Lower interior glass temperature becomes noticeable over time.

Installation Conditions That Preserve Gains

Triple pane benefits materialize when:

- Full removal installs are used

- Continuous air sealing is integrated

- Cold-rated spacers and flexible seals are present

Without this, the third pane’s benefit erodes quickly.

When Triple Pane Windows Do Not Make Sense (Critical)

This section is non-negotiable for decision accuracy.

Not Worth It in Already Airtight Homes

Triple pane often adds little value when:

- The home was built after 2000

- Blower-door results show low air leakage

- Interior temperatures are consistent

Limiting factor

:

Wall and air-barrier performance already dominate heat loss.

Not Worth It When Installation Quality Is Uncertain

Triple pane is a poor choice when:

- Retrofit inserts are used

- Wall access is limited

- Sealing methods are inconsistent

Limiting factor

:

Installation quality caps performance regardless of glass configuration.

Not Worth It When Budget Trade-Offs Exist

Many homeowners overpay when:

- Funds could improve attic or rim-joist sealing

- Heating costs are already moderate due to gas pricing

Limiting factor

:

ROI is lower than alternative envelope upgrades.

Double vs Triple Pane in Edmonton — Real-World Comparison

| Configuration | Expected Performance Outcome | Who It Fits |

|---|---|---|

| High-quality double pane | Strong comfort, lower cost | Most post-1990 homes |

| Average triple pane | Marginal improvement | Rarely optimal |

| Triple pane with full air-sealing | Noticeable comfort gain | Older, draft-prone homes |

| Double pane + envelope sealing | Best ROI in many cases | Majority of Edmonton housing |

Important note

:

Alberta’s relatively low natural gas prices extend the payback period for triple pane upgrades compared to provinces with higher energy costs.

Scenario Table — Where the Extra Pane Changes the Outcome (and Where It Doesn’t)

The most reliable way to compare double vs triple pane in Edmonton is not by abstract performance, but by scenario control variables: air leakage, wall insulation, exposure, and installation access.

| Scenario (Edmonton) | What dominates heat loss | Double pane outcome | Triple pane outcome | Practical note |

|---|---|---|---|---|

| Pre-1980 detached, visible drafts | Air leakage + weak wall insulation | Noticeable improvement if airtight install is achieved | Larger comfort gain if airtight install is achieved | If drafts remain, both underperform; sealing is the gate. |

| 1990s two-storey, moderate leakage | Perimeter leakage + mixed insulation | Often the best cost-to-comfort ratio | Smaller incremental gain | Triple pane can help comfort in large openings, but ROI is slower. |

| Post-2000 home, tight envelope | Heating distribution + ventilation balance | Typically sufficient | Often marginal | People overpay when pane count is used to solve non-window problems. |

| Wind-exposed site (open corridor, corner lot) | Pressure-driven infiltration | Depends on seal/frame quality more than pane count | Depends on seal/frame quality more than pane count | “Tighter” beats “thicker”: air control decides comfort. |

| Large glazing area (living room picture window) | Radiant loss + glass surface temperature | Can feel cold near glass in deep winter | Can reduce radiant discomfort | Comfort benefit can be real even if utility savings are modest. |

This table also explains why Edmonton homeowner feedback varies so widely. Two homes can buy the same window configuration and get opposite outcomes because the controlling variable is usually not the glass — it is the envelope and install compatibility.

Common Myths About Triple Pane Windows in Edmonton

Myth — “Triple pane always means warmer rooms”

Reality

:

Air leakage often dominates comfort loss.

How to verify

:

Perform a smoke or incense test around window perimeters during cold weather.

Myth — “ENERGY STAR guarantees Edmonton performance”

Reality

:

ENERGY STAR certification reflects laboratory testing, not field installation.

How to verify

:

Inspect spacer type, seal flexibility, and installation method.

Myth — “New windows fix cold rooms automatically”

Reality

:

Cold rooms often result from wall insulation gaps or air leakage paths.

How to verify

:

Infrared imaging during winter conditions reveals true loss points.

Edmonton-Specific Scenarios (Context, Not Promotion)

Pre-1980 Neighbourhoods

Homes built before modern air-barrier standards often experience:

- Cold perimeter walls

- Persistent condensation

- Uneven room temperatures

Triple pane windows can help only when paired with proper air sealing.

1990s Suburban Housing

Many of these homes show:

- Reasonable wall insulation

- Moderate window leakage

Here, well-installed double pane units combined with sealing often outperform triple pane retrofits.

Wind-Exposed Areas

Open layouts increase pressure differences. In these cases:

- Frame rigidity

-

Seal durability

matter more than pane count.

Infill and Renovations — Why “New Windows” Sometimes Make an Older House Feel Worse

A common Edmonton pattern is a renovated older home with new finishes but an incomplete envelope strategy. The windows get replaced first because they are visible and expensive, but the surrounding wall system still behaves like an older structure.

Two things often happen in these infill-style renovations:

-

The house becomes tighter in some places but not others.

The new windows reduce leakage at the opening, but air still moves through rim-joists, attic bypasses, or unsealed transitions. This can create pressure shifts that make one room feel draftier than before, even when the windows are technically better. -

Humidity and condensation behavior changes.

When part of the envelope is tightened, interior humidity can rise unless ventilation is adjusted. Homeowners then blame the windows for condensation, when the real issue is a changed moisture balance. Triple pane can reduce center-of-glass condensation, but it will not prevent perimeter condensation if air leakage remains at trim lines or if humidity is high.

This is why Edmonton upgrades should be evaluated as a system. Sometimes the “right” answer is not a pane count change, but identifying whether the discomfort is driven by infiltration, wall insulation gaps, or ventilation imbalance.

Window Performance Over Time in Edmonton

What Fails After 5–10 Years (and Why It Matters More Than Initial Specs)

One of the most misleading aspects of window discussions is that most comparisons focus on day-one performance. Edmonton’s climate makes this approach unreliable.

What matters more is how a window system behaves after years of sustained cold stress, repeated freeze cycles, and pressure exposure.

Why Edmonton Accelerates Window Aging

Edmonton imposes a unique stress profile on window assemblies:

- Long uninterrupted cold seasons

- Repeated contraction and expansion cycles

- Extended periods where materials remain below their elasticity thresholds

- Wind-driven pressure that continuously tests seals

These conditions do not typically cause sudden failure. Instead, they produce gradual degradation, which is harder to detect and easier to misdiagnose.

Seal Shrinkage Over Time

Most window seals are designed to remain flexible within a certain temperature range. In Edmonton:

- Prolonged exposure below −25 °C causes seals to stiffen

- Repeated contraction cycles reduce rebound capacity

- Micro-gaps form at sash contact points

This results in:

- subtle drafts

- increased infiltration during windy conditions

- reduced surface temperatures near edges

Importantly, triple pane windows increase seal dependency. With more glass mass, the tolerance for seal degradation becomes smaller, not larger.

Spacer Fatigue and Edge Performance Decline

Spacers experience some of the most extreme stress in cold climates.

Over time:

- Differential movement between glass panes increases

- Thermal bridging concentrates cold at the edges

- Moisture migration becomes more likely

This often presents as:

- edge condensation

- frost patterns at corners

- reduced effective insulation area

Triple pane configurations rely heavily on spacer integrity. If spacers are not cold-rated for long-duration exposure, edge performance can deteriorate faster than expected.

Frame Sagging and Hardware Stress

Frames and hardware experience cumulative effects:

- Vinyl contraction can affect alignment

- Heavier triple pane units place greater load on hinges

- Locking mechanisms lose compression pressure

After 5–10 years, this may result in:

- difficulty closing or locking windows

- reduced airtightness under pressure

- increased infiltration during cold snaps

These are performance failures, not cosmetic ones.

Installation Aging Effects

Installation choices made at replacement time often define long-term performance.

Common issues include:

- Spray foam shrinkage over time

- Missing or discontinuous interior air seals

- Exterior sealing focused on water control only

Edmonton’s cold amplifies these weaknesses. What initially felt “tight” can slowly become leaky without obvious visual cues.

ENERGY STAR and Certification Limits in Edmonton

ENERGY STAR labels are often cited as proof of suitability. In Edmonton, this assumption deserves scrutiny.

What ENERGY STAR Actually Tests

ENERGY STAR certification evaluates:

- U-factor

- Solar heat gain coefficient

- Air leakage under controlled conditions

Testing occurs in laboratory environments with:

- stable temperatures

- controlled pressure

- ideal installation assumptions

This creates a useful baseline, but not a complete picture.

What ENERGY STAR Does Not Capture

ENERGY STAR does not account for:

- long-duration cold exposure

- seal elasticity loss over time

- frame contraction under extreme cold

- installation variability

- wind-driven infiltration

As a result, two ENERGY STAR-rated windows can perform very differently in real Edmonton homes.

ENERGY STAR ratings should be treated as a minimum compliance threshold, not a performance guarantee. In Edmonton, where environmental stress exceeds laboratory assumptions, real-world outcomes depend far more on assembly durability and installation quality than on label classification.

How to Read a Window Label in Practical Terms (What to Check Beyond the Badge)

In Edmonton, a label is useful only if it helps you verify the assembly. Certification marks are not meaningless, but they do not answer the questions that matter most in field performance: edge temperature, seal durability, and air control.

When reviewing a rated window, the practical checks are:

-

U-factor versus “felt comfort”:

U-factor is helpful for comparing glass packages, but comfort complaints in Edmonton are often perimeter-driven. A slightly better U-factor does not compensate for poor perimeter sealing. -

Air leakage rating (if provided) and what it implies:

Even good lab air-leakage numbers can be defeated by installation gaps. Treat lab airtightness as “potential performance,” not guaranteed performance. -

Spacer and edge design:

The edge of glass is where Edmonton problems show first: frost at corners, edge condensation, and cold bands near frames. “Warm-edge” systems reduce thermal bridging, but the real-world result depends on seal longevity and build quality. -

Compatibility with installation method:

A high-performance unit installed as an insert into an old frame can leave original leakage paths intact. In that case, label performance becomes theoretical.

A useful way to think about certification is this: it tells you a window can perform under controlled conditions. In Edmonton, you still need to confirm whether the assembly and installation strategy will preserve that performance through long-duration cold and wind pressure.

Why Pane Count Alone Is Misleading

ENERGY STAR ratings may suggest:

- triple pane = superior performance

But in practice:

- airtightness matters more

- frame and spacer quality dominate long-term results

- installation quality often outweighs glass configuration

This is why some Edmonton homeowners report no noticeable comfort improvement after upgrading to triple pane units.

ROI Reality in Edmonton. Energy Savings vs Practical Payback

Return on investment calculations often assume ideal conditions. Edmonton’s economics complicate this.

Natural Gas Pricing and Payback

Alberta’s relatively low natural gas prices mean:

- energy savings from additional insulation layers translate into smaller dollar amounts

- payback periods for triple pane upgrades extend significantly

In many cases:

- the comfort improvement is real but subtle

- the financial return is long-term rather than immediate

This does not mean triple pane is ineffective. It means financial expectations must be realistic.

Where Triple Pane ROI Improves

ROI becomes more favourable when:

- the home has high baseline heat loss

- rooms near windows are consistently uncomfortable

- envelope upgrades are limited or impractical

In these cases, triple pane can reduce discomfort even if energy savings alone do not justify the cost.

Where ROI Often Disappoints

Triple pane ROI is weakest when:

- the home already has good airtightness

- heating costs are modest

- discomfort is driven by walls, not windows

In these situations, homeowners often feel they “paid for specs” rather than outcomes.

Financial ROI vs Comfort ROI (Why They Often Diverge)

Energy savings calculations focus on fuel reduction, but homeowners experience value primarily through comfort stability.

In Edmonton, triple pane windows may:

- slightly reduce heating demand

- noticeably reduce radiant cold near glass

- improve comfort without dramatically lowering bills

This creates a divergence where financial ROI appears weak, but comfort ROI is tangible.

Problems arise when homeowners expect energy savings alone to justify the upgrade. In many cases, triple pane windows should be evaluated as comfort-stabilizing components, not cost-saving investments.

Recognizing this distinction prevents disappointment and aligns expectations with actual outcomes.

Noise Reduction in Edmonton — Why Pane Count Is Not the Main Factor

Although not the main focus of this article, sound performance often enters the conversation.

Why Triple Pane Is Often Overcredited

Triple pane windows are commonly assumed to be quieter. In reality:

- sound reduction depends more on glass asymmetry and lamination

- equal-thickness panes transmit certain frequencies efficiently

- airtightness matters more than pane count

Edmonton Noise Context

Noise sources in Edmonton include:

- major arterial roads

- LRT corridors

- industrial and rail activity

In these cases:

- laminated glass

-

asymmetric pane thickness

often outperform standard triple pane units.

Edmonton Climate Volatility. Why Window Stress Is Increasing, Not Decreasing

Climate patterns affecting Edmonton have become more erratic.

Increased Cold Snaps and Temperature Swings

Recent years have seen:

- sharper temperature drops

- more frequent polar vortex intrusions

- rapid transitions between mild and extreme cold

These changes increase:

- seal fatigue

- material stress

- condensation risk

Window systems designed for “average cold” face growing challenges.

Freeze–Thaw Cycling Effects

Repeated freeze–thaw cycles:

- weaken seal bonds

- accelerate material aging

- increase moisture migration risk

This reinforces the importance of durable assemblies, not just initial performance ratings.

Decision Framework. How to Choose Between Double and Triple Pane in Edmonton

This framework summarizes the logic developed throughout the article.

Step 1 — Assess the House, Not the Weather

Ask:

- When was the home built?

- Is airtightness already good?

- Are walls or windows the dominant comfort issue?

If walls dominate, glass upgrades alone will disappoint.

Step 2 — Identify the Real Discomfort Driver

Cold rooms are caused by:

- air leakage

- thermal bridging

-

insufficient insulation

more often than by glass conduction alone.

Triple pane helps surface temperature, but not infiltration.

Step 3 — Match the Window System to the Envelope

Triple pane makes sense when:

- envelope upgrades are limited

- window openings are large

- sustained cold dominates comfort perception

Double pane is often sufficient when:

- airtightness is strong

- walls perform well

- heating distribution is even

Step 4 — Prioritize Installation Quality

Installation decisions determine:

- long-term airtightness

- condensation patterns

- durability under cold stress

In Edmonton, installation quality can outweigh pane choice.

Final Decision Gate — Do Not Buy Triple Pane If

Triple pane windows are not appropriate if:

- airtightness testing shows low leakage

- wall insulation is the dominant weakness

- installation quality cannot be verified

- budget limits prevent proper sealing

In these cases, triple pane glass risks becoming a high-cost solution applied to a low-impact problem.

Common Misdiagnoses in Edmonton Homes

Understanding what windows cannot fix is just as important.

“The windows are new, so they can’t be the problem”

New windows can still:

- leak air

- lack proper sealing

- be mismatched to wall systems

Age alone does not guarantee performance.

“Triple pane should have solved this”

When comfort does not improve, the cause is often:

- envelope leakage

- missing air barriers

- thermal bridges elsewhere

Blaming glass configuration delays real solutions.

Calm Expert Conclusion. How to Decide Without Overbuying

Edmonton’s extreme cold makes window decisions feel high-stakes, but clarity comes from understanding limits.

Triple pane windows can improve comfort in specific conditions:

- older, leaky homes

- wind-exposed sites

- situations where wall upgrades are impractical

They are not a universal solution.

In many Edmonton homes, airtight installation, frame quality, and envelope continuity matter more than adding a third pane. Double pane systems, when properly selected and installed, often deliver comparable comfort with better cost balance.

The most reliable decisions are made by:

- evaluating the building first

- identifying the true source of heat loss

- choosing a window system that fits the house, not the label

Cold climate performance is about system behavior over time, not just specifications on day one.

1000’s of Colours & Textured Finishes

Transform your home from ordinary to extraordinary with our new coloured and non-glare textured finishes. Available in a wide array of colours as well as custom matched colours for your very own personalized design.

Our Most Popular Replacement Window Colours: