Window Glass Terminology Explained for Canadian Homes

Key Takeaways

- Double-pane and double-glazed windows refer to the same basic insulated glass structure. The difference is regional terminology, not construction.

- Thermal pane (thermopane) is not a separate window type. It typically describes a higher-performance insulated glass unit with gas fills, Low-E coatings, and improved sealing.

- Window performance is determined by U-value, gas fill, Low-E coatings, spacer technology, and seal quality, not by the label used in marketing.

- In Canada, properly built insulated glass units reduce heat loss, condensation, drafts, and indoor noise while improving year-round comfort.

- ENERGY STAR® ratings and CSA standards are more reliable indicators of performance than terms like “double-glazed” or “thermal pane.”

- Installation quality is critical. Even the best glass unit can underperform if it is not sealed and installed correctly.

- For most Canadian homes, high-quality double-pane (thermal pane) windows offer the best balance of efficiency, comfort, and long-term value.

Double-Pane, Double Glazed, Thermal Pane (Thermopane) and What Actually Matters

When Canadian homeowners begin researching new windows , they often encounter a cluster of terms that sound similar but appear to promise different levels of performance: double-pane , double-glazed , thermal pane , and thermopane . These terms are frequently used interchangeably across websites, sales conversations, and contractor quotes, which leads many homeowners to believe they are choosing between fundamentally different products.

In reality, most of the confusion stems from terminology, regional language, and marketing shorthand, not from radically different window technologies. The real performance of a window is determined by how the insulated glass unit is constructed, how well it is sealed, and how it performs in climate conditions.

This guide consolidates terminology into a single, clear, authoritative resource. Instead of comparing labels, it explains what each term actually means, how modern insulated glass works, and which specifications truly impact comfort, energy efficiency, durability, and long-term value for Canadian homes.

Why Window Terminology Causes Confusion

The window industry did not develop its terminology in one place or at one time. As a result, different regions adopted different words to describe the same core technology.

In North America, double-paned window s became the standard . In the United Kingdom, Europe, and Australia, the same construction was referred to as double-glazed . Later, as insulated glass technology improved, the term thermal pane (or thermopane ) emerged to describe higher-performing sealed glass units.

Over time, these terms began to overlap. Today, they are often used to describe similar products with varying performance levels, making it difficult for homeowners to understand what they are actually paying for.

As Tony Wong, Project Manager at Canadian Choice Windows & Doors , explains:

“Homeowners often assume that ‘double-glazed’ or ‘thermal pane’ automatically means better performance. In practice, the terminology tells you very little. What matters is what’s inside the glass unit and how well it’s built.”

The Foundation: Insulated Glass Units (IGUs)

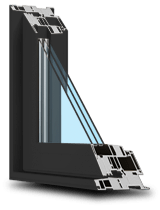

Nearly all modern residential windows in Canada are built around an Insulated Glass Unit (IGU). An IGU is a sealed glass assembly designed to reduce heat transfer, control condensation, and improve indoor comfort.

A standard IGU consists of:

- Two or more panes of glass

- A spacer system that maintains a consistent gap between panes

- A sealed cavity filled with air or inert gas

- Desiccant materials are inside the spacer to absorb moisture

- Primary and secondary sealants that keep the unit airtight

This structure creates a thermal barrier. Instead of heat moving freely through a single sheet of glass, it must pass through multiple layers and an insulating cavity, which dramatically reduces heat loss in winter and heat gain in summer.

All of the terms discussed in this guide refer to variations of IGUs, not completely different window systems.

What “Double-Pane” Means in Practice

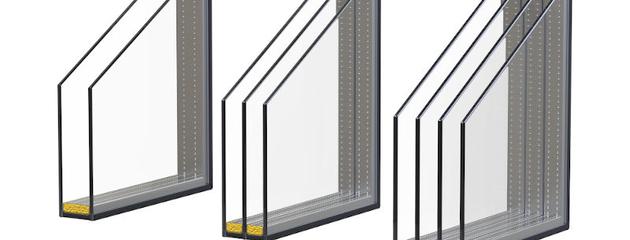

A double-pane window simply means that the insulated glass unit contains two panes of glass separated by a sealed cavity. That is the baseline definition.

What the term does not tell you is:

- Whether the cavity is filled with air or gas

- Whether the glass has Low-E coatings

- What type of spacer is used

- How durable are the seals are

As a result, two windows, both described as “double-pane,” can perform very differently. One may be entry-level, while another may meet or exceed modern energy-efficiency standards.

In Canada, high-quality double-pane windows typically include argon gas fills and Low-E coatings as standard features, while lower-end products may still rely on air-filled cavities with minimal thermal enhancement.

What “Double Glazed” Actually Refers To

Double-glazed is a regional term, not a different technology.

In the UK and Europe, the word glazing refers to the installation of glass within a frame. A double-glazed window, therefore, means a window with two panes of glass installed as a sealed unit.

Structurally, a double-glazed window and a double-pane window are the same thing. In Canada, the term “double-glazed” is sometimes used to describe newer or upgraded double-pane systems, but the construction principles remain the same.

The key takeaway is that double-pane and double-glazed are not competing categories. There are different names for the same type of insulated glass assembly.

What Is a Thermal Pane (Thermopane) Window?

The term thermal pane (or thermopane ) is best understood as a performance-oriented description, not a structural one.

A thermal-pane window typically refers to a double-pane insulated glass unit that includes:

- Argon or krypton gas fills

- One or more Low-E coatings

- Advanced warm-edge spacer systems

- High-quality dual sealants

In other words, thermal pane windows are upgraded double-pane windows designed to minimize heat transfer and maintain performance over time.

Helen Sin, Consumer Success Manager at Canadian Choice Windows & Doors , summarizes it clearly:

“Thermal pane isn’t about adding buzzwords. It’s about how well the window keeps your home comfortable through winters and summers.”

Summary Table

| Term | What It Describes | What It Does Not Guarantee |

|---|---|---|

| Double-pane | Two panes of glass | Energy efficiency level |

| Double glazed | Same as double-pane | Gas fill or coatings |

| Thermal pane | High-performance IGU | A specific brand or standard |

| Thermopane | Industry shorthand | Triple glazing |

What Actually Determines Window Performance

Rather than focusing on labels, Canadian homeowners should evaluate measurable performance factors that directly affect comfort, energy bills, and durability.

Gas Fill: Air vs Argon vs Krypton

The cavity between panes is a critical part of insulation.

- Air is the least effective insulator and is now considered outdated

- Argon is denser than air, slows heat transfer, and offers an excellent balance of cost and performance

- Krypton provides even higher insulation but is typically reserved for narrow cavities due to cost

Most ENERGY STAR®-certified Canadian windows use argon gas as standard.

Low-E Coatings Explained

Low-E (low emissivity) coatings are microscopically thin metallic layers applied to the glass surface. They reflect infrared heat while allowing visible light to pass through.

In winter, Low-E coatings reflect indoor heat back into the home. In summer, they reduce solar heat gain. This dual function improves comfort without darkening the room or blocking daylight.

The number and placement of Low-E layers can vary depending on climate zone and window orientation.

Spacer Technology and Edge Performance

Spacers hold the panes apart and contain the desiccant. Older aluminum spacers conduct heat, often creating cold edges and condensation.

Modern warm-edge spacers, made from stainless steel, silicone foam, or composite materials, reduce thermal bridging and improve long-term seal durability. This has a noticeable impact on comfort near the window perimeter.

Understanding U-Value (Lower Is Better)

U-value measures how much heat passes through the window. The lower the number, the better the insulation.

| Window Configuration | Typical U-Value (W/m²·K) |

|---|---|

| Older double-pane (air-filled) | 1.6–1.8 |

| Double-pane with argon + Low-E | 1.2–1.4 |

| High-performance thermal pane | ~1.2 or lower |

These differences translate directly into reduced heat loss and lower energy costs during Canadian winters.

Why This Matters for Canadian Climate Conditions

Homes across Canada face long heating seasons, wide temperature swings, and dry indoor air during winter. When windows are poorly insulated, homeowners often experience drafts, condensation, uneven room temperatures, and rising heating costs.

According to Natural Resources Canada, upgrading to high-efficiency windows can reduce household energy use by up to 20 percent, depending on the home and region.

More importantly, properly built insulated glass units improve day-to-day comfort, which is often the first thing homeowners notice after replacement.

Noise Reduction and Indoor Comfort

Insulated glass also improves acoustic performance. Sound waves lose energy as they pass through multiple panes and insulating cavities.

| Window Type | Typical Sound Reduction |

|---|---|

| Single pane | 20–25 dB |

| Standard double-pane | 30–35 dB |

| Thermal pane | 35–40 dB |

For homes near traffic, schools, or urban centres, this difference can significantly improve indoor comfort.

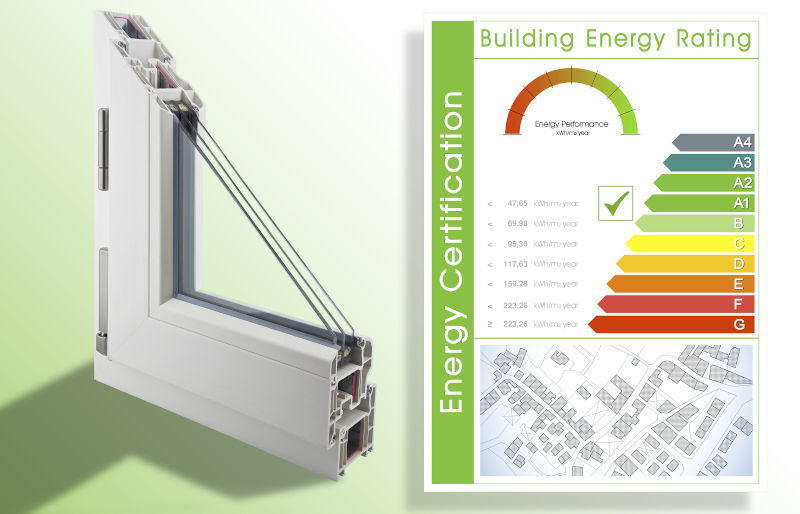

Energy Ratings and Canadian Building Codes

Canadian building codes do not mandate specific glazing terminology. Instead, they set performance thresholds.

Key standards include:

- ENERGY STAR® Canada

- CSA A440

- National Building Code of Canada

Both high-quality double-pane and thermal-pane windows can meet or exceed these standards when properly manufactured and installed. Installation quality remains critical, as even the best glass unit can underperform if improperly sealed.

Where Triple-Pane Windows Fit In

Triple-pane windows add a third pane of glass and a second insulating cavity. This increases thermal resistance and acoustic performance but also adds cost and weight.

For most Canadian homes, high-quality thermal-pane double-pane windows provide the best balance of efficiency, cost, and return on investment. Triple glazing is typically reserved for extreme climates or specific comfort needs.

What Homeowners Should Focus On Instead of Labels

When reviewing window quotes or specifications, prioritize:

- U-value and ENERGY STAR® certification

- Type of gas fill

- Low-E coating configuration

- Spacer system design

- Warranty coverage

- Installation standards

These factors have a measurable impact on performance and longevity, regardless of whether the product is described as double-pane, double-glazed, or thermal pane.

Final Perspective

Window terminology can be misleading, but performance is not.

Most modern Canadian homes benefit from well-built, insulated glass units that are engineered for local climate conditions. When homeowners focus on specifications, certifications, and installation quality rather than labels, they make decisions that deliver long-term comfort, efficiency, and peace of mind.

That philosophy reflects how Canadian Choice Windows & Doors approaches window design and education: clear explanations, proven performance, and solutions built for real Canadian homes.

FAQ — Window Glass Terminology

Are double-pane and double-glazed windows the same?

Yes. Both terms describe windows with two panes of glass separated by a sealed insulating cavity. “Double-pane” is commonly used in North America, while “double-glazed” is more common in Europe and the UK. Structurally, they are the same.

What is a thermal pane (thermopane) window?

A thermal pane window typically refers to a higher-performance double-pane insulated glass unit. It usually includes argon or krypton gas fills, Low-E coatings, warm-edge spacers, and improved sealing to reduce heat transfer.

Are thermal pane windows more energy efficient than standard double-pane windows?

They can be. Thermal pane windows usually include upgraded components that lower U-values and improve insulation. However, energy efficiency depends on the full glass configuration, not the term itself.

Which window term should homeowners trust when comparing options?

None of the terms alone. Homeowners should compare measurable specifications such as U-value, ENERGY STAR® certification, gas fill type, Low-E coatings, and spacer technology.

Do double-pane windows meet Canadian building codes?

Yes. High-quality double-pane windows with proper gas fills and Low-E coatings can meet or exceed Canadian building code and ENERGY STAR® requirements.

Are triple-pane windows always better than thermal pane windows?

Not always. Triple-pane windows provide higher insulation but cost more and are heavier. For most Canadian homes, well-built thermal-pane double-pane windows offer excellent performance and value.

Why does installation quality matter as much as the glass itself?

Poor installation can allow air leaks, moisture intrusion, and heat loss, reducing performance regardless of glass quality. Proper sealing and fitting are essential for long-term comfort and efficiency.

1000’s of Colours & Textured Finishes

Transform your home from ordinary to extraordinary with our new coloured and non-glare textured finishes. Available in a wide array of colours as well as custom matched colours for your very own personalized design.

Our Most Popular Replacement Window Colours: