What Window Frames Are Best for Coastal Areas in Ontario?

Key Takeaways

- Environmental conditions near lakes are tough — Salt air, humidity, strong winds, and freeze-thaw cycles all accelerate wear on window frames.

- Vinyl frames are a top choice for coastal homes thanks to their resistance to moisture, rot, and corrosion. They also offer excellent insulation and require little maintenance.

- Aluminum frames are strong and stylish, especially when coated or anodized, but need protection against corrosion and may underperform in insulation if not thermally broken.

- Impact-resistant windows add protection against wind, debris, and storms — ideal for exposed properties near Lake Ontario or Georgian Bay.

- Certifications matter — Look for ENERGY STAR® and NAFS ratings to ensure durability, efficiency, and resistance to air and water infiltration.

- Maintenance is key — Regular cleaning, seal inspections, and proper installation extend the life of your windows in challenging coastal climates.

What environmental factors affect window frame performance in Ontario’s coastal areas?

Imagine your home perched near the edge of Lake Ontario or the shoreline of Georgian Bay. It’s beautiful, but it also means your windows are constantly at odds with nature. The environmental stressors in coastal zones are no joke. They affect not just your view, but the structural integrity of your window frames.

Salt Air

Freshwater coasts don’t have the same salinity levels as oceanic regions, but localized industrial activity and lake-effect weather patterns can increase the salt content in the air. Over time, this salt settles onto window surfaces and accelerates corrosion, especially for metallic components.

High Humidity

Living near the lake means more than great views — it also brings moisture that can sneak into window frames and slowly cause damage. Persistent moisture can seep into frame joints, promoting mould growth, rot (in wood), and swelling in moisture-sensitive materials. Even when sealed, frames can develop micro-leaks over time, especially during extreme temperature fluctuations.

Strong Winds

Whether it’s winter storms or summer squalls, coastal regions are subject to gusts that test window seals and framing rigidity. Repeated pressure changes can weaken structural joints and distort materials that lack proper reinforcement.

Freeze-Thaw Cycles

Perhaps the biggest culprit in material degradation, alternating freeze-thaw cycles can wreak havoc on any building material. Water enters microscopic cracks, freezes, and expands, repeating this process over several seasons. For window frames, this means:

- Loss of seal integrity

- Cracking and warping in rigid materials

- Frame movement leading to energy inefficiency

Coastal Conditions Require Material-Specific Solutions

Experts from Canadian Choice Windows & Doors emphasize the importance of selecting frame materials with proven resistance to these challenges.

Tony Wong, Project Manager , explains:

"We don’t just install windows — we engineer them for the specific environment. Coastal homes need more than beauty. They need resilience."

How do aluminum window frames perform in coastal environments?

Aluminum window frames are a common choice for both residential and commercial properties due to their strength and modern appearance. But how do they fare when pitted against Ontario's coastal conditions?

Durability

Let’s start with the good news. Aluminum is robust, allowing for thinner frames and larger glass surfaces without compromising structural integrity. It's non-combustible and resistant to physical wear, making it ideal for high-wind locations.

Corrosion Resistance

This is where aluminum’s story gets complex. Raw aluminum corrodes quickly when exposed to salt or humid air. However, most window frames are anodized or coated with thermally broken finishes that dramatically enhance corrosion resistance.

Comparative Durability Table

| Feature | Aluminum (Coated) | Vinyl |

|---|---|---|

| Strength | Excellent | Moderate |

| Corrosion Resistance | Good | Excellent |

| Moisture Resistance | Moderate | Excellent |

| Thermal Insulation | Fair | Good |

| Cost | High | Moderate |

Thermal Performance

Aluminum conducts heat, which is both a strength and a weakness. Without proper thermal breaks, aluminum frames can create cold spots and reduce overall window efficiency. When engineered with advanced thermal barriers, they meet energy code requirements but still may underperform compared to vinyl in terms of insulation.

Are vinyl window frames suitable for Ontario’s humid coastal regions?

Vinyl window frames — typically made from polyvinyl chloride (PVC) — are among the most popular options in Ontario. They're affordable, low-maintenance, and energy efficient. But can they handle the unique demands of coastal environments?

Moisture Resistance

Vinyl is inherently resistant to moisture. Unlike wood or untreated metal, it doesn’t absorb water or rot. This makes it an excellent choice for high-humidity environments, where other materials might degrade over time.

Insulation Value

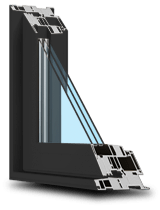

Vinyl provides strong thermal insulation. Its non-conductive properties mean it won’t transmit heat or cold easily, contributing to stable indoor temperatures. Double or triple-pane glass with gas fills further enhances this energy efficiency.

Expansion and Contraction

Now here’s the catch: PVC is more prone to thermal expansion and contraction than aluminum. During freeze-thaw cycles or summer heatwaves, vinyl can:

- Warp under excessive sun exposure

- Stress window seals

- Create alignment issues if not correctly installed.

Proper reinforcement with metal cores and professional-grade installation can offset these risks. Canadian Choice Windows & Doors offers solutions that account for this variability.

What are the pros and cons of aluminum vs vinyl windows in coastal areas?

When it comes to choosing the right window material for your coastal Ontario home, it helps to weigh the advantages and drawbacks side by side. Aluminum and vinyl both offer distinct benefits, but each comes with trade-offs that can affect long-term performance, maintenance, and cost.

Pros and Cons Table

| Feature | Aluminum | Vinyl |

|---|---|---|

| Corrosion Resistance | Good (if coated/anodized) | Excellent |

| Thermal Insulation | Fair (needs thermal break) | Excellent |

| Structural Strength | Excellent | Moderate |

| Maintenance | Low (with coating) | Very low |

| Aesthetics | Sleek, modern look | Versatile but less premium |

| Cost | Higher initial investment | Budget-friendly |

| UV Resistance | Excellent (with powder coating) | Moderate to good (depends on quality) |

Aluminum is the right call for strength and minimal profiles — but only when upgraded with protective coatings. Vinyl excels in energy efficiency and cost savings, particularly when reinforced.

What are impact-resistant windows, and are they necessary in Ontario?

If you’ve lived through a significant windstorm or seen wind-driven debris crash through glass, the term “impact-resistant windows” carries weight. But are these reinforced systems necessary in Ontario's coastal regions?

What Are Impact-Resistant Windows?

Impact-resistant windows are specially designed to withstand high-velocity impacts, such as flying debris from storms. These windows typically consist of:

- Laminated glass with interlayers of polyvinyl butyral (PVB)

- Reinforced frames that can absorb shock without failing

- Locking mechanisms to prevent structural blowout

Why They Matter in Coastal Ontario

While Ontario doesn't face hurricanes like Florida, it does experience:

- Intense thunderstorms and wind gusts exceeding 100 km/h

- Freezing rain that can break standard glass

- Hail events, especially in spring and summer

Safety and Insurance Benefits

Impact-resistant windows offer:

- Increased security against break-ins

- Noise reduction

- Potential insurance discounts in high-risk areas

Should You Get Them?

If your home is near open water or on a high elevation exposed to prevailing winds, impact-resistant windows might be a wise upgrade. While not mandatory, they align well with future-proofing strategies.

Which window frame materials offer the best resistance to corrosion?

When it comes to corrosion, not all frames are created equal. Сoastal climate demands materials that can endure moisture, wind, and airborne pollutants.

Material Rankings for Corrosion Resistance

- Vinyl (PVC) – Fully resistant to rot and rust, low maintenance

- Aluminum (coated or anodized) – Strong with protective finish, but still susceptible if damaged

- Treated Wood – Looks great, but needs regular sealing and can degrade if neglected

Choosing Based on Environment

For homes in areas with:

- High salt exposure → Choose vinyl

- Mixed weather with strong winds → Coated aluminum

- Heritage districts → Consider treated wood, but plan for more maintenance

Think of corrosion resistance as protection that pays off for decades to come. Choose materials rated for durability, and don’t overlook professional installation to ensure longevity in Ontario’s dynamic coastal climate.

What certifications or ratings should you look for in coastal windows?

Certifications aren’t just technical jargon — they're essential indicators of how well a window can perform under pressure. In coastal Ontario, where homes are exposed to wind, moisture, and variable temperatures, selecting windows with the proper certifications ensures durability and energy efficiency.

ENERGY STAR®

ENERGY STAR is a trusted mark backed by the U.S. Environmental Protection Agency and Natural Resources Canada. For coastal homes, look for:

- ENERGY STAR Most Efficient designation

- Ratings suited for Zone 2 or Zone 3 (Ontario’s colder regions)

ENERGY STAR–certified windows offer:

- Better insulation

- Reduced energy bills

NAFS – North American Fenestration Standard

The NAFS rating system is key to understanding a window’s performance under physical stress.

- Air infiltration rating : critical for wind-prone coastal regions

- Water penetration resistance : vital for rain and lake-effect conditions

- Structural wind load resistance : confirms window integrity in high gusts

How do coastal conditions affect window lifespan and maintenance needs?

While materials, manufacturing, and installation affect window longevity, exposure to coastal environments dramatically accelerates wear and tear. Lakeshore environments introduce factors such as airborne salt, humidity, and repeated freeze-thaw cycles that can erode even the most robust materials.

Typical Lifespan by Material

| Material | Average Lifespan (coastal use) | Notes |

|---|---|---|

| Vinyl | 20–25 years | Low maintenance |

| Coated Aluminum | 20–30 years | Needs periodic recoating |

| Treated Wood | 15–20 years | Requires annual sealing |

| Fibreglass | 25–35 years | Highly durable but expensive |

Maintenance Tips for Coastal Homes

- Clean frames regularly to remove salt and grime

- Inspect seals and caulking twice a year, especially after winter.

- Apply corrosion-resistant coatings to metal components.

- Lubricate moving parts to prevent rust and maintain smooth operation.

What are the best windows for areas with a humid climate?

In high-humidity environments, window frames must resist moisture-related damage, such as mould, warping, and condensation buildup. Coastal zones — especially in summer — create ideal conditions for topics such as those unless the right materials and designs are in place.

Best Materials for Humidity

- Vinyl (PVC) – Moisture-repellent, doesn’t rust or rot.

- Aluminum (coated) – Needs treatment, but holds up if maintained.

Avoid These Pitfalls

- Uncoated aluminum or raw wood can absorb moisture, leading to swelling or decay.

- Poor insulation increases the chance of indoor condensation and energy los.s

Health and Energy Benefits

- Less condensation = lower mould risk and better indoor air quality

- Energy-efficient models reduce HVAC strain in humid summers.

What’s the final verdict on the best coastal window frames in Ontario?

After all the comparisons and considerations, the decision often comes down to priorities — strength, aesthetics, energy efficiency, or low maintenance. So, which material leads the pack for lakeside homeowners?

Best Frame Types by Feature

| Criteria | Best Material | Notes |

|---|---|---|

| Corrosion Resistance | Vinyl | No rust, no rot |

| Energy Efficiency | Vinyl | Excellent insulation |

| Structural Strength | Aluminum (coated) | Withstands wind and impact |

| Cost Efficiency | Vinyl | Affordable and long-lasting |

| Maintenance Level | Vinyl | Easy to clean and repair |

| Aesthetics | Aluminum / Wood | Sleek or traditional, depending on style |

Trusted Recommendations

- Vinyl windows : Ideal for most homeowners — durable, efficient, and cost-effective

- Coated aluminum : Great for modern design and strength, but requires some upkeep.

“We usually recommend vinyl solutions for coastal zones,” says Helen Sin . “They offer the best balance of durability and value, especially in harsh seaside conditions.”

1000’s of Colours & Textured Finishes

Transform your home from ordinary to extraordinary with our new coloured and non-glare textured finishes. Available in a wide array of colours as well as custom matched colours for your very own personalized design.

Our Most Popular Replacement Window Colours: