Best Windows for Net-Zero Homes in Canada

Across Canada, from icy prairies to coastal rain belts, homeowners are discovering that high-performance windows are becoming an increasingly important part of sustainable home design. They don’t just let in light; they manage energy, shape indoor climate, and define how efficiently a house can truly perform.

Yet, here’s the surprising truth: even in new construction, many so-called “energy-efficient” homes still can lose a significant portion of heat through outdated window systems, particularly in colder regions. That’s why architects, engineers, and homeowners alike are rethinking what a window can do.

This guide explores how advanced glazing technologies, materials, and certifications are shaping modern net-zero home design in Canada.

Key Takeaways

- Windows play a important role in achieving actual net-zero energy performance by managing heat gain and loss, as well as natural light.

- Selecting the right glazing, frame material, and gas fill can help reduce thermal transfer and boost insulation.

- Understanding U-factor, Solar Heat Gain Coefficient (SHGC), and air leakage ratings helps homeowners make informed energy-efficient choices.

- Expert input from Canadian Choice Windows & Doors™ specialists reinforces the connection between design, comfort, and sustainability.

How Windows Affect Energy Efficiency in Net-Zero Homes

Walk through any net-zero home in Canada, and you’ll quickly notice that the windows are different — thicker, tighter, and surprisingly warm to the touch even in winter. That’s no coincidence. In energy-efficient construction , windows are both an opportunity and a vulnerability. They can either leak conditioned air and undermine heating systems or, when engineered correctly, act as passive energy moderators.

The Science of Thermal Transfer

Heat moves naturally from warm areas to cold ones through conduction, convection, and radiation. Windows interrupt this exchange through insulation layers, gas fills, and specialized coatings. The less heat that passes through, the better. This is where the U-factor comes in — a key metric that measures heat loss. In Canada’s colder climate zones, homeowners should look for U-factors of 1.4 W/m²K or lower to ensure superior insulation.

Understanding SHGC and Air Leakage

The Solar Heat Gain Coefficient (SHGC) measures the amount of solar radiation that enters through the glass. A higher SHGC can be beneficial for south-facing windows in winter, helping capture sunlight and reduce heating needs. But for west- or east-facing exposures, lower SHGC values minimize summer overheating. Balance is key.

Meanwhile, air leakage ratings reveal how tightly sealed the window is. Even the most advanced glazing won’t perform if air infiltrates around the frame. Net-zero designs, therefore, emphasize high-performance weatherstripping and precision installation.

The Role of Insulation Value

Windows with multi-chambered frames, insulated spacers, and argon or krypton gas fills reduce convective currents within the glazing unit. Combined with triple-pane windows, this layered insulation limits unwanted heat transfer. The outcome? Stable indoor temperatures and lower energy loads on HVAC systems.

Tony Wong, Project Manager at Canadian Choice Windows & Doors™ , explains: “When homeowners think of efficiency, they often start with walls or roofs. But a single poorly insulated window can cancel out the gains from an entire wall of insulation. Every unit has to perform as part of the whole building envelope.”

What Types of Windows Are Best Suited for Net-Zero Homes in Canada?

Canada’s diverse climate — from maritime humidity to prairie cold — requires window systems that can adapt to extremes. Not every model performs equally, which is why specification matters. Below are the most effective options for net-zero construction.

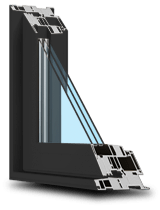

Triple Glazing

Triple-glazed windows consist of three panes of glass separated by gas-filled cavities, offering the best defence against thermal loss. The additional layer traps air, reducing convection and enhancing noise reduction. This design is especially beneficial for northern regions where temperature swings are sharp and sustained.

Low-E Glass

Low-E coatings act like invisible mirrors, reflecting infrared energy back into the room in winter and outward in summer. Different coating types — soft-coat and hard-coat — serve distinct regional needs. In cooler climates, soft-coat Low-E glass offers optimal insulation and clarity.

Inert Gas Fills

Argon and krypton gases are denser than air, providing superior insulation between panes. Argon is cost-effective and ideal for most applications, while krypton performs better in narrow cavities but at a higher cost. Many Canadian builders combine these gases for balanced performance.

Composite and Fibreglass Frames

Frame material significantly influences overall thermal efficiency. Fibreglass and composite frames outperform traditional aluminum, which conducts heat easily. Vinyl remains a popular choice for its affordability, but high-end composites ensure durability, stability, and minimal expansion or contraction during temperature fluctuations.

| Window Type | Insulation Performance | Durability | Typical Application |

|---|---|---|---|

| Triple-Glazed Low-E | Excellent | High | All climate zones |

| Double-Glazed Low-E | Good | Moderate | Mild or mixed climates |

| Fibreglass Frame | Excellent | Very High | Coastal and northern regions |

| Vinyl Frame | Good | High | Urban residential |

| Aluminum (Thermally Broken) | Moderate | Very High | Commercial buildings |

Helen Sin, Consumer Success Manager at Canadian Choice Windows & Doors™ , notes: “Energy-efficient glazing isn’t just about comfort — it’s about long-term savings and environmental responsibility. The right window choice can reduce annual energy use by up to 25%.”

Why Is Window Choice Critical in Net-Zero Home Design?

Even the most advanced HVAC system or insulated wall can’t compensate for inefficient windows. A net-zero home relies on a continuous, airtight building envelope, where every component works synergistically.

Windows as the Weak Point

In a typical home, windows account for 30–40% of total heat loss. Older models with single-glazed windows or aluminum frames act like open conduits for energy loss. Modern, energy-rated units reduce this loss to under 10%, preserving the home’s thermal balance.

Daylighting and Solar Control

Natural light isn’t just an aesthetic bonus — it directly impacts energy use. Strategically positioned, high-performance windows can offset the need for artificial lighting, reducing electricity demand. Combined with shading devices and reflective coatings, they control glare while maintaining brightness.

The Design Perspective

Architects now integrate window systems into holistic net-zero strategies — not afterthoughts. Orientation, glazing ratios, and frame depth all determine performance. A well-placed, thermally broken window can even contribute to passive solar heating.

Canadian Choice Windows & Doors™ offers a range of products designed precisely for these parameters. Explore more about our energy-efficient windows and installation options tailored to your region.

Which Window Certifications Support Net-Zero Home Goals in Canada?

Window certifications act as a guarantee of performance, confirming that a product meets national and international energy-efficiency standards. For builders and homeowners aiming for net-zero targets, choosing windows with reliable certification labels ensures compliance and consistency across the entire building envelope.

ENERGY STAR® Canada

ENERGY STAR® Canada remains the most widely recognized certification for energy-efficient windows. Administered by Natural Resources Canada (NRCan), it evaluates products based on:

- U-factor (W/m²·K) – measures insulation performance. Lower values mean better efficiency.

- Solar Heat Gain Coefficient (SHGC) – indicates how much solar energy passes through.

- Air Leakage (AL) – rates the amount of air infiltration through the assembly.

Products labelled with the ENERGY STAR® logo are tested for Canada’s distinct climate zones (1-3), ensuring that northern installations meet stricter insulation requirements.

Learn more : Natural Resources Canada – ENERGY STAR® Windows

NFRC Certification

The National Fenestration Rating Council (NFRC) label provides standardized testing recognized across North America. It includes:

- Visible Transmittance (VT) – measures natural light passage.

- Condensation Resistance (CR) – evaluates moisture prevention.

- Uniform testing criteria – allowing comparison across brands.

NFRC certification complements Canadian standards, giving cross-border builders a consistent benchmark for performance and transparency.

Passive House Certification

For ultra-low energy buildings, Passive House (Passivhaus) certification sets the world’s highest benchmark. To meet these standards, windows must achieve:

- U-values ≤ 0.8 W/m²K

- Airtight installation integration

- Optimized solar gain for passive heating

Passive House-certified windows are typically triple-glazed with insulated frames and warm-edge spacers. Although more expensive, they dramatically reduce heating demand — critical for achieving net-zero or even net-positive results.

| Certification Label | Focus | Key Metrics | Governing Body | Link |

|---|---|---|---|---|

| ENERGY STAR® Canada | National energy rating | U-factor, SHGC, AL | Natural Resources Canada | nrcan.gc.ca |

| NFRC | North American testing standard | VT, CR, U-factor | National Fenestration Rating Council | nfrc.org |

| Passive House | Ultra-efficiency benchmark | U ≤ 0.8 W/m²K | Passive House Institute | passivehouse.com |

What Window Materials Offer the Best Performance for High-Efficiency Homes?

The material of a window frame has as much impact on energy performance as the glazing itself. It determines insulation capacity, longevity, and maintenance requirements. Here’s a detailed comparison of the most common materials used in high-performance residential construction.

Vinyl (uPVC)

Vinyl remains one of Canada’s most popular window materials due to its low cost, durability, and good insulation value. It resists moisture and doesn’t require repainting. However, it can expand or contract with temperature changes, which affects long-term sealing if not properly reinforced.

Fiberglass

Fibreglass frames are dimensionally stable and have low thermal conductivity. They can be filled with insulating foam and often outperform vinyl in structural rigidity. Ideal for both cold and coastal climates, fibreglass offers excellent air sealing and minimal warping.

Wood-Clad Composites

These combine the thermal insulation of wood with the low maintenance of aluminum or vinyl cladding. Interior wood surfaces provide natural warmth and moisture control, while exterior cladding protects against weather. They’re a premium choice for luxury and sustainable builds.

Thermally Broken Aluminum

Traditional aluminum is a poor insulator, but modern thermally broken designs introduce an insulating barrier between inner and outer sections. This significantly reduces heat transfer, allowing use in large, modern window designs without energy loss.

| Material Type | Insulation (U-Factor Potential) | Durability | Maintenance | Best Use |

|---|---|---|---|---|

| Vinyl (uPVC) | 1.4–1.8 W/m²K | High | Very Low | Suburban & moderate climates |

| Fiberglass | 1.2–1.5 W/m²K | Very High | Low | Cold or coastal zones |

| Wood-Clad Composite | 1.0–1.4 W/m²K | High | Medium | Luxury & eco-friendly builds |

| Thermally Broken Aluminum | 1.6–2.0 W/m²K | Very High | Low | Contemporary urban designs |

What Role Do Windows Play in Total Envelope Performance for High-Efficiency Homes?

In the quest for high-efficiency and net-zero homes, windows are not isolated elements — they are integrated components of the building envelope system. Their role is to maintain air barrier continuity and support the thermal balance of walls, roofs, and foundations.

Air Barrier Continuity

Windows must seamlessly integrate with the home’s air barrier system. Any disruption at the junctions between window frames and wall assemblies allows air leakage and moisture intrusion. Advanced sealing systems, such as multi-layer membranes and spray foam integration, ensure complete continuity.

Thermal Envelope Synergy

The thermal envelope — comprising insulation, air barriers, and glazing — works as a cohesive energy shield. High-performance windows with insulated spacers and warm-edge technologies reduce temperature fluctuations and condensation risks.

Integration with Design and Construction

Coordinating window placement, insulation depth, and structural transitions ensures that no cold bridges or air leaks compromise the building’s integrity. Continuous collaboration between architects, engineers, and window manufacturers creates the airtightness essential for net-zero certification.

Can Window Upgrades Alone Move a House Toward Net-Zero Status?

Upgrading windows is one of the most impactful retrofit strategies for improving home energy performance — but can it, on its own, move a house toward actual net-zero status? The short answer is: partially. While efficient windows dramatically reduce heating and cooling demands, reaching net-zero requires a holistic approach that includes insulation, airtightness, and renewable energy systems.

Retrofit Potential

Replacing outdated single-pane or low-quality double-pane units with ENERGY STAR®-rated or triple-glazed Low-E windows can reduce total household energy consumption by 15–25%, depending on climate zone and existing insulation levels. This improvement lowers the baseline energy load, making it easier to offset remaining usage with renewable systems such as solar panels.

Older homes often lose energy through poorly sealed frames and uninsulated cavities. Upgrading windows fixes these leaks while improving comfort and soundproofing. In cold Canadian winters, high-performance windows prevent cold drafts and condensation, thereby improving indoor air quality.

Cost-Benefit Analysis

Window upgrades are a long-term investment, often offering payback periods of 8–15 years, depending on energy prices and local rebates. Homeowners benefit from:

- Reduced heating and cooling costs year-round

- Enhanced property value

- Greater comfort and sound reduction

- Qualification for energy efficiency incentives (such as the Canada Greener Homes Grant )

However, costs can vary significantly. Triple-pane units with composite frames cost more upfront but deliver superior thermal performance. Paired with energy modelling, these upgrades can identify the balance between cost and return.

Energy Modelling Comparison

Energy modelling provides quantitative insight into how much window upgrades alone contribute to net-zero progress.

| Scenario | Average U-Factor (W/m²·K) | Annual Energy Use (kWh/m²) | Energy Savings vs. Baseline | Net-Zero Potential Contribution |

|---|---|---|---|---|

| Existing Double-Glazed Vinyl | 2.4 | 125 | Baseline | — |

| ENERGY STAR® Triple-Glazed | 1.3 | 105 | 16% reduction | Moderate |

| Passive House-Certified Windows | 0.8 | 85 | 32% reduction | High |

For homeowners, these performance differences translate into steadier indoor temperatures, lower peak heating demand, and improved comfort during extreme weather.

Why High-Performance Windows Are Key to Net-Zero Homes in Canada

Achieving net-zero energy use is not about a single feature — it’s about synergy. Yet within that balance, windows play a unique and central role. They regulate heat, harness sunlight, and maintain airtightness, acting as both a thermal barrier and a natural energy gateway.

Summary of Findings

- Energy Efficiency: High-performance windows with low U-factors and optimized SHGCs can reduce heating and cooling loads by 30–40%.

- Comfort and Durability: Advanced frames and gas-filled glazing stabilize indoor temperatures and prevent condensation.

- Aesthetic and Passive Design Integration: Proper orientation and daylighting reduce reliance on artificial lighting and HVAC systems.

Product Selection Tips

- Match window type to climate zone. In northern Canada, triple glazing with argon or krypton gas is essential.

- Look for ENERGY STAR® and Passive House labels. These ensure verified, independent testing and compliance.

- Choose durable frame materials. Fibreglass or composite frames minimize expansion, ensuring long-term airtightness.

- Verify professional installation. Even the best windows underperform when the sealing or flashing is poor.

Window Features for Net-Zero Success

| Performance Feature | Target Metric | Contribution to Net-Zero |

|---|---|---|

| U-Factor | ≤ 1.4 W/m²·K | Reduces heat loss in winter |

| SHGC | 0.3–0.5 | Balances solar gain and shading |

| Airtight Installation | ≤ 0.1 L/s·m² | Prevents drafts and moisture entry |

| Low-E Coating | High reflectivity | Improves year-round insulation |

| Frame Type | Fibreglass/Composite | Limits expansion and increases durability |

Sources Used

- Natural Resources Canada – ENERGY STAR® Windows

- Canadian Green Building Council

- Building Science Corporation, High-Performance Building Envelopes Report (2023)

- Passive House Institute, Window Performance Criteria (2024)

Final Note

:

High-performance windows are no longer a luxury — they’re a foundational component in many modern, energy-conscious Canadian homes. Whether as part of a retrofit or a new build, they represent one of the most important links between sustainability, comfort, and architectural integrity.

FAQ

What are the best windows for net-zero homes in Canada?

Triple-glazed Low-E windows with fibreglass or composite frames are ideal for Canadian climates. They reduce heat loss, improve comfort, and help balance solar gain for net-zero energy performance.

Do ENERGY STAR® windows make a big difference?

Yes. ENERGY STAR®-rated windows can cut energy loss by up to 25%, lowering heating costs and improving indoor comfort while meeting Canadian climate zone requirements.

Are triple-pane windows worth the investment?

In many cases, triple-pane windows provide clear benefits in colder Canadian climates, though suitability depends on budget, orientation, and overall building design. Although they cost more initially, triple-pane windows reduce drafts, condensation, and long-term energy bills, providing a solid return on investment.

Can upgrading windows alone achieve a net-zero home?

Not entirely. While energy-efficient windows can reduce total household energy consumption by up to 20%, achieving net-zero also requires insulation upgrades, airtightness, and integration of renewable energy.

What certifications should I look for?

Look for ENERGY STAR® Canada, NFRC, and Passive House labels. These certifications guarantee independent testing, verified insulation values, and compliance with net-zero energy standards.

1000’s of Colours & Textured Finishes

Transform your home from ordinary to extraordinary with our new coloured and non-glare textured finishes. Available in a wide array of colours as well as custom matched colours for your very own personalized design.

Our Most Popular Replacement Window Colours: