The Role of Window Spacers in Preventing Condensation and Heat Loss

Key Takeaways

- Window spacers are crucial components in modern insulated glass units (IGUs), separating panes while reducing heat transfer.

- They significantly impact energy efficiency, helping to maintain indoor temperatures and reduce utility costs.

- Double-pane window spacers help form a thermal break, reducing condensation.

- Warm edge spacers outperform traditional aluminum spacers in thermal performance and durability.

- Canadian Choice Windows & Doors utilizes advanced spacer technologies to enhance the efficiency of its windows.

What is a window spacer, and why is it important in modern windows?

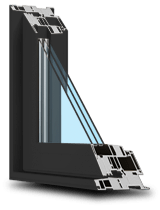

In double or triple-glazed windows, the panes are kept evenly spaced by a component called a window spacer. This component, known as a window spacer, plays a more critical role than its simple appearance suggests.

A window spacer is the thin, often metallic or composite strip that separates the layers of glass in an Insulated Glass Unit (IGU). It plays a vital role in maintaining the structural integrity of the window, ensuring proper sealing, and optimizing thermal performance. Without it, you wouldn't have the energy savings or condensation resistance that modern windows are known for.

The Role of Window Spacers in IGUs

Window spacers sit between the panes of glass in an IGU, maintaining a consistent gap — typically filled with inert gas such as argon or krypton — to provide insulation. Their responsibilities include:

- Maintaining the glass gap is crucial for achieving proper insulation.

- Sealing the perimeter: Keeping moisture out and gas in.

- Managing thermal stress: By absorbing or minimizing expansion and contraction from temperature changes.

These functions directly influence a window's R-value (thermal resistance) and U-factor (rate of heat loss).

Spacer Technology and Thermal Efficiency

Older spacers made of aluminum, while structurally sound, are highly conductive. That means they transfer heat easily between the interior and exterior — precisely what energy-efficient designs aim to avoid.

Modern spacers, especially warm-edge spacers, are designed to reduce this conductivity, significantly improving a window’s thermal efficiency. According to the U.S. Department of Energy, warm edge spacers can improve a window’s overall U-factor by up to 10%.

Performance Factors

Several aspects affect how well a spacer performs:

- Material composition (metallic vs. composite)

- Gas retention rate

- Resistance to moisture penetration

- Flexibility and structural durability

In the words of Helen Sin, Consumer Success Manager at Canadian Choice Windows & Doors:

“Window spacers may be small components, but they play a critical role in overall thermal performance — directly influencing energy efficiency and reducing the workload on HVAC systems.”

How do double-pane window spacers contribute to energy savings?

To understand this, think of the space between two panes of glass as a barrier. It’s not just empty air — usually it’s filled with argon or krypton gas to slow the movement of heat. But even this gap needs structure to remain consistent, and that’s where spacers come in.

Creating a Thermal Break

The thermal break is a critical feature in double-pane windows. Spacers reduce thermal bridging — the process by which heat travels through materials, such as metal. In traditional aluminum spacers, this bridging is significant, which undermines insulation. Spacers with low conductivity help prevent this.

- Low-conductivity spacers : Reduce heat flow

- Gas-filled cavities : Retain more stable indoor temperatures

- Dual-seal systems : Ensure long-term gas retention and performance

Preventing Condensation

Condensation often forms when indoor humidity meets a cold windowpane or glass surface. Poor spacer performance results in edge-of-glass temperature drops, triggering condensation. With improved spacer technology:

- The edges stay warmer

- Moisture accumulation is minimized.

- The window remains clearer, longer.

This not only boosts visibility but also protects the window frame and wall from mould and rot.

Spacer Impact on Double Pane Performance

| Feature | Poor-Quality Spacer | High-Performance Spacer |

|---|---|---|

| Thermal Break Efficiency | Low | High |

| Condensation Resistance | Weak | Strong |

| Energy Savings Potential | Minimal | Significant |

| Gas Retention | Poor | Excellent |

| Long-Term Durability | Short lifespan | Long-lasting |

What is the difference between warm-edge spacers and traditional aluminum spacers?

When comparing window options, understanding the difference between warm-edge spacers and aluminum spacers is crucial for making an informed decision.

Traditional Aluminum Spacers

Aluminum spacers have been the industry standard for decades. They are:

- Highly conductive: Transfers heat easily

- Structurally rigid: Durable but inflexible

- Poor at moisture control: Higher risk of condensation

These characteristics make them reliable structurally, but they’re not ideal for today’s energy standards.

Warm Edge Spacer Technology

Warm edge spacers are made from materials like stainless steel, foam, or composite polymers. Their goal? To dramatically reduce thermal conductivity.

Key advantages:

- Lower thermal conductivity: Reduces edge heat loss

- Improved condensation resistance: Keeps window edges warmer

- Enhanced longevity: Less stress on sealants

- Flexible design: Absorbs expansion/contraction better

In side-by-side tests, warm edge designs consistently outperform aluminum in moisture control, durability, and energy retention.

Thermal Conductivity Comparison

| Property | Aluminum Spacer | Warm Edge Spacer |

|---|---|---|

| Thermal Conductivity | High (bad) | Low (good) |

| Durability | Medium | High |

| Condensation Resistance | Low | High |

| Cost | Lower upfront | Higher upfront, better ROI |

Why This Matters in Canadian Climates

In colder climates, such as Canada’s, windows are subjected to extreme temperature fluctuations. Warm edge spacers handle this much better by maintaining internal temperature stability. That’s particularly crucial when windchills drop and your heating system works overtime.

How does window caulking work alongside window spacers for insulation?

When it comes to windows, insulation is only as strong as its weakest point. Caulking and spacers play different but complementary roles in preventing drafts and heat loss.

Step-by-Step Guide: How Caulking and Spacers Work Together

- A spacer system is placed between two panes of glass to create an insulating glass unit (IGU).

- Primary sealant bonds the spacer to the glass, ensuring no gas leakage.

-

Secondary sealant (caulking) is applied around the IGU’s perimeter to:

- Prevent water penetration

- Block air leaks

- Reinforce structural stability

- Once installed, exterior caulking around the window frame seals the unit to the wall, complementing the internal spacer.

The result: A two-layer defence — the spacer controls condensation inside the glass, while caulking blocks outside air and water.

H3: Are warm-edge spacers worth the investment for homeowners?

Warm edge spacers — made from non-metallic, low-conductivity materials — are designed to reduce heat transfer along the edge of a window. But do they justify the cost?

Benefits of Warm Edge Spacers

- Lower heat loss : Up to 65% improvement compared to traditional aluminum spacers.

- Reduced condensation : Keeps interior glass edges warmer.

- Energy savings : Decreases heating bills during Canadian winters.

- Improved comfort : Less draftiness near windows.

- Resale value: Energy-efficient features are beautiful to buyers.

Cost vs. Long-Term Savings

- Initial cost increase : ~$15–$20 more per window compared to standard spacers.

- Payback period : 3–6 years, depending on energy costs and window size.

- Long-term value : Lifespan often matches or exceeds that of the IGU (15–25 years).

According to Natural Resources Canada , homes with high-efficiency windows can save up to 12% annually on heating costs — and spacers play a key role in this savings.

Expert Note

"In colder climates such as Toronto, warm edge spacers are strongly recommended," says Tony Wong . "They pay for themselves quickly and add lasting comfort."

What materials are used in warm-edge window spacers today?

The term “warm edge” covers a family of materials that all aim to minimize thermal bridging. In 2025, manufacturers are refining their formulas for both durability and insulation.

Types of Warm Edge Spacer Materials

| Material Type | Lifespan | Thermal Performance | Pros | Cons |

|---|---|---|---|---|

| Foam (silicone-based) | 15–20 years | Excellent | Very low conductivity, flexible | Can degrade under UV exposure |

| Structural Silicone | 20–25 years | High | Strong adhesion, durable, flexible | Higher cost |

| Hybrid Polymers | 20–25 years | Very high | Combines flexibility with strength | Newer tech, fewer long-term studies |

How do window spacers help prevent condensation and mould growth?

Condensation is more than a cosmetic issue — it can trigger mould growth, wood rot, and poor indoor air quality. Window spacers play a critical role by controlling the temperature of the glass edge.

How Spacers Prevent Condensation

- Thermal insulation : Warm edge spacers reduce the transfer of cold from outside to inside.

- Edge temperature balance : By keeping the inner glass edge warmer, they reduce the likelihood of water vapour condensing.

- Moisture control : Dry air between panes (sealed with desiccants) absorbs residual humidity, preventing fogging.

Standard vs. Warm Edge Spacer Performance

| Feature | Standard Aluminum Spacer | Warm Edge Spacer (Foam/Polymer) |

|---|---|---|

| Glass Edge Temp | Cold, prone to condensation | Warmer, reduces condensation risk |

| Mold Risk | Higher in humid climates | Significantly lower |

| Energy Efficiency | Low | High |

Can I replace or upgrade window spacers without replacing the entire window?

This is one of the most common homeowner questions. Unfortunately, spacers are not designed to be swapped out like hardware.

Spacer Retrofitting: Is It Possible?

- Not typically feasible : Spacers are sealed inside the insulated glass unit (IGU). Accessing them requires dismantling the sealed panes.

- Cost factor : Attempting to replace a spacer usually costs as much — or more — than replacing the entire IGU.

- Best practice : Replace the IGU itself while retaining the original frame if it’s still in good condition.

When Full Replacement Is Needed

- Spacer seal failure (fogging, dirt between panes)

- Broken or cracked glass

- Severe condensation that recurs despite caulking

While caulking can extend a window’s life, replacing spacers usually requires replacing the entire IGU.

What are the signs of spacer failure in double or triple-pane windows?

Knowing when a spacer has failed can save energy costs and prevent structural issues.

Step-by-Step Signs to Look For

- Fogging between panes – trapped moisture indicates seal failure.

- Visible dirt or debris inside the unit – suggests air leakage.

- Condensation streaks – often appearing along the edge of the glass.

- Glass feels colder than usual – energy efficiency is compromised.

- Rising energy bills – heating or cooling loss through failed insulation.

What maintenance tips extend the life of window spacers and seals?

Window spacers and seals don’t require much day-to-day attention, but small habits can add years to their lifespan.

Step-by-Step Maintenance Guide

- Inspect caulking annually – Look for cracks or peeling and reapply exterior-grade caulking where needed.

- Keep weep holes clear – Blocked drainage can trap water and accelerate seal failure.

- Clean with gentle products – Avoid harsh chemicals near window edges, as they can degrade sealants.

- Manage indoor humidity – Keep levels between 30–50% to reduce condensation pressure on seals.

- Avoid pressure washing – High-pressure sprays can force water into sealed edges.

Which window spacer is right for your home?

Choosing the right spacer isn’t just about cost — it’s about climate, comfort, and long-term performance.

Spacer Types

| Spacer Type | Pros | Cons | Best For |

|---|---|---|---|

| Aluminum (Standard) | Affordable, widely available | High conductivity, condensation risk | Short-term budget builds |

| Foam | Excellent thermal performance | Can degrade under UV over time | Energy-focused retrofits |

| Structural Silicone | Durable, strong adhesion | Higher cost | Harsh climates, long-term builds |

| Hybrid Polymers | Best balance of flexibility + strength | New tech, limited long-term data | Premium, high-performance homes |

Style & Performance Checklist

- Do you live in a cold climate? - Choose warm edge or hybrid spacers.

- Do you need a budget-friendly fix? - Standard aluminum still works, but has drawbacks.

- Is resale value a priority? - Energy-efficient hybrid or silicone options boost appeal.

1000’s of Colours & Textured Finishes

Transform your home from ordinary to extraordinary with our new coloured and non-glare textured finishes. Available in a wide array of colours as well as custom matched colours for your very own personalized design.

Our Most Popular Replacement Window Colours: