How Does the Weather Affect Your Windows and Doors?

Key Takeaways

- Extreme cold and heat cause material contraction and expansion, leading to cracks, seal failure, and warping in poorly installed or low-quality windows and doors.

- Condensation is not just a cosmetic issue — it indicates humidity imbalance or poor insulation and can result in mould and frame damage if ignored.

- Material choice matters: Vinyl, aluminum, and wood respond differently to heat, cold, and moisture. Selecting the right one for your regional climate is essential for long-term durability.

- Energy-efficient windows with low-E coatings and gas-filled glazing offer superior protection against temperature extremes and moisture-related issues.

- Poor installation multiplies weather-related damage, even if you have premium products. Certified installation is crucial to seal integrity and long-term performance.

- Routine seasonal maintenance — including caulking inspection, weatherstripping checks, and ventilation control — can prevent costly repairs and prolong window life.

- Weather sealing, window films, and shading systems are effective add-ons that help buffer your home from climate extremes year-round.

- Older windows degrade with time, making them more vulnerable to drafts, leaks, and insulation failure. Replacing them with modern units is often a smart, cost-saving upgrade.

How does cold local winter weather impact your windows?

When the temperature dips sharply during Canadian winters, the very structure of your windows is put to the test. It's not just about frost on the glass — extreme cold can lead to mechanical and structural failures.

The science of contraction in cold temperatures

Materials expand and contract based on temperature changes. This is introductory thermodynamics, but the implications for your windows are substantial. In freezing temperatures, especially below -20°C, materials like vinyl and aluminum contract significantly. If your windows aren't built to accommodate this movement, the result can be:

- Cracks in glass or frame joints

- Seal failure in double or triple-glazed units , leading to foggy or moisture-laden panes

- Decreased energy efficiency , as heat escapes through compromised seals

Signs of winter damage

If you notice any of the following, your windows may be suffering from cold-weather fatigue:

- Interior fogging between panes

- Difficulty opening or closing due to frame warping

- Drafts even when the windows are shut

Maintenance tip: Inspect caulking and weatherstripping annually, ideally before winter sets in.

What causes condensation on windows in winter and summer?

Condensation seems simple: glass water. However, the underlying physics is far more complex, and understanding it is key to preventing related issues like mould and frame rot.

The physics of condensation

Condensation forms when moist air comes into contact with a surface at or below its dew point. In winter, the cold inner surface of the window causes moisture from indoor air to condense. In summer, it can happen on the exterior due to indoor cooling.

Impact of humidity and air circulation

Humidity control is crucial. Ideal indoor humidity levels are:

- 30% to 50% in winter

- 40% to 60% in summer

Too much humidity indoors leads to condensation, especially on single-glazed or poorly insulated windows. Poor air circulation around windows can also exacerbate the problem.

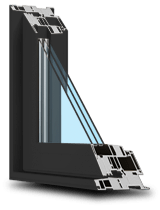

The role of window glazing

Single-pane windows:

- Offer minimal insulation

- More prone to interior condensation in winter

Double-pane windows:

- Better insulation

- Reduced condensation risk due to thermal buffer

Triple-pane windows:

- Excellent insulation

- Often used in passive homes or very cold climates

Condensation Risk by Glazing Type

| Glazing Type | Winter Condensation Risk | Summer Exterior Fogging | Energy Efficiency Rating |

|---|---|---|---|

| Single Pane | High | Low | Poor |

| Double Pane | Moderate | Moderate | Good |

| Triple Pane | Low | Moderate | Excellent |

Solutions to condensation problems

- Use a hygrometer to monitor indoor humidity

- Improve ventilation with HRV systems or bathroom/kitchen fans

- Upgrade to double or triple-glazed windows with gas fills and low-E coatings

Can summer heat cause window frame warping or deformation?

Yes, and it’s more common than most homeowners think. During summers, window frames — especially those in direct sun — can experience temperatures well over 50°C.

Material sensitivity to heat

Let’s break down how different materials handle thermal stress:

Material Sensitivity to Summer Heat

| Material | Deformation Risk | Notes |

|---|---|---|

| PVC | High | Can soften and lose structural form |

| Vinyl | Moderate | May warp with prolonged sun exposure |

| Wood | Moderate | Can crack or split if untreated |

| Aluminium | Low | Excellent resistance, but conducts heat |

Manufacturer warnings and guidelines

Most window manufacturers specify a safe temperature range for storage and installation. For example, PVC windows should not be installed in direct sunlight above 30°C without shade provisions. Failure to adhere to these can void warranties.

Prevention tips

- Install exterior shading systems like awnings or pergolas

- Use UV-protective coatings on window glass

- Choose frames with reinforced internal structures to resist warping

What’s the takeaway? Matching your window material to your regional climate is crucial.

"Selecting window materials suited to your regional climate isn’t just about optimizing energy efficiency — it’s also critical to ensuring long-term structural performance," says Tony Wong, Project Manager at Canadian Choice Windows & Doors . "Materials that can withstand temperature swings, UV exposure, and humidity will maintain their integrity and appearance far longer."

Why do older windows show more signs of weather damage?

As windows age, the materials and seals that once offered top-tier protection begin to degrade. This degradation is a slow process, but becomes increasingly evident with years of exposure to weather extremes.

Age-related vulnerabilities

- Seal degradation: Over time, seals around the glass and frames lose elasticity and adhesion. This allows moisture intrusion and reduces insulation.

- Glass fogging: Moisture penetration leads to internal condensation that can’t be wiped away.

- Insulation failure: The insulating gases (like argon) in double or triple-glazed units may escape, significantly reducing thermal performance.

Product lifecycle and durability

Window manufacturers often list a lifespan of 15 to 25 years , depending on materials and maintenance.

- Vinyl windows typically last 20 years

- Wood windows , if well maintained, can exceed 30 years

- Aluminum windows may last over 25 years, but require periodic frame inspection

Industry data on window replacement

Data shows that homes built before 1990 are significantly more likely to have windows with:

- Reduced U-factor performance

- Higher air leakage rates

- Greater susceptibility to rot or corrosion

Modern energy codes and CSA standards have improved durability and efficiency, making window upgrades a cost-effective investment.

Are energy-efficient windows better at resisting weather damage?

Absolutely. Modern energy-efficient windows are engineered not just for thermal performance but also for durability under a range of weather conditions.

Key components that resist weather damage

- Low-E (Low Emissivity) coatings : Reflect UV and infrared rays, reducing heat build-up and frame stress

- Argon or krypton gas fills : Provide superior insulation, protecting against condensation and thermal shifts

- Insulated frames : Multi-chambered or foam-filled designs resist warping and cracking

Energy Star ratings and performance

Windows with Energy Star certification in Canada meet stringent CSA performance criteria, including:

- U-factor : Lower values mean better insulation

- Solar Heat Gain Coefficient (SHGC) : Controls the amount of solar radiation admitted

- Air leakage : Tested to ensure minimal draftiness

How can poor installation worsen the impact of weather on doors and windows?

Even the best windows and doors will underperform — or outright fail — if improperly installed. Poor installation not only reduces energy efficiency but also significantly increases vulnerability to weather damage.

Key installation errors to watch for

- Improper sealing : Gaps and poorly applied caulking allow air and moisture to seep in

- Level misalignment : Uneven frames can stress the structure and cause operational issues

- Lack of waterproof barriers : Without sill pans or membrane flashing, water infiltration becomes almost inevitable

Real-world consequences

These issues often result in:

- Drafts and condensation, even in new units

- Premature frame rot or rusting

- Warping and structural damage during freeze-thaw cycles

Checklist of professional installation standards

- Ensure the frame is plumb, level, and square

- Use appropriate shims and fasteners for secure anchoring

- Apply continuous beads of waterproof sealant

- Install drip caps, sill pans, and flashing membranes

- Perform air leakage and water infiltration tests post-installation

Always insist on certified installation professionals to ensure compliance with Canadian building codes.

What routine maintenance reduces weather-related window issues?

Proactive maintenance is your first line of defence against climate-related window problems. With seasonal inspections and a few simple tasks, you can extend the life of your windows significantly.

Seasonal inspection tips

- Spring : Check for winter-related seal damage, clean exterior panes, test operation

- Summer : Inspect caulking, repaint wood frames if needed, check insect screens

- Fall : Clean weep holes and drainage channels, examine weatherstripping

- Winter : Look for condensation, monitor for drafts, ensure windows shut tightly

Homeowner maintenance checklist

- Inspect all caulking and reapply where cracked

- Clean interior and exterior glass

- Vacuum dirt from tracks and drainage holes

- Replace or adjust weatherstripping

- Lubricate moving parts with silicone spray

- Check screens for tears or loose frames

- Use a hygrometer to monitor indoor humidity

A small investment of time each season can prevent costly repairs and even extend the overall lifespan of your window systems.

What are the most weather-resistant window and door materials available?

Not all window and door materials are created equal regarding weather resistance. Some hold up well under heat but fail in extreme cold or wet conditions. Others provide excellent all-season durability but come at a higher upfront cost.

Material breakdown by resistance type

| Material | Heat Resistance | Cold Resistance | Moisture Resistance | Durability |

|---|---|---|---|---|

| Vinyl | Good | Moderate | Good | 20-25 yrs |

| Aluminium | Excellent | Excellent | Moderate | 25-30 yrs |

| Wood | Poor-Moderate | Moderate | Poor unless treated | 15-30 yrs* |

*Dependent on maintenance and treatment

Cost-benefit analysis

- Vinyl : Affordable and low maintenance, but may warp in prolonged heat exposure.

- Aluminum : Robust and thermally stable, but can conduct heat and cold without thermal breaks.

- Wood : Aesthetic appeal, but high maintenance and rot risk if not regularly sealed.

Choose based on your regional climate, budget, and long-term maintenance willingness.

Can window tints or films help protect against weather damage?

Absolutely. Window tints and films are not just cosmetic — they offer real functional benefits regarding energy efficiency and weather protection.

Key benefits of window films

- UV filtering : Blocks up to 99% of harmful UV rays, protecting both interior furnishings and window materials.

- Heat reduction : Reflective coatings can reduce solar heat gain by 30–70%.

- Glare control : Enhances comfort and visibility inside the home, especially in sun-heavy rooms.

Myths vs. facts

- Myth : Tints always make windows darker — Fact : Many modern films are nearly invisible but still effective.

- Myth : Films damage window glass — Fact : Only incompatible films applied to non-tempered glass may cause thermal stress.

- Myth : Tints void warranties — Fact : Manufacturer-approved films are often warranty-compatible.

Product comparisons

| Brand | UV Blocking | Heat Rejection | Visibility |

|---|---|---|---|

| 3M Prestige | 99% | Up to 60% | High |

| Llumar | 99% | 50–60% | Medium |

| Gila Heat Control | 98% | Up to 65% | Medium |

How does weather sealing actually work around doors and windows?

Weather sealing is your barrier against the elements, and it functions through a variety of materials and installation strategies designed to keep air and water out.

Types of weather sealing

- Weather stripping : Applied around movable components like doors and sashes to block drafts

- Foam insulation : Expands to fill gaps during window installation, preventing air leakage

- Threshold barriers : Seals under doors to stop wind and rain from entering

How it works

Sealing systems compress or expand to fill voids where materials meet. This not only prevents air leakage but also reduces energy bills and moisture-related damage.

What’s the best long-term strategy for protecting windows from weather damage?

The key to long-term weather resistance lies in a multi-pronged strategy that combines quality materials, proper installation, routine maintenance, and timely upgrades.

Summary of best practices

- Choose aluminum frames for high weather exposure

- Install low-E, argon-filled glazing with CSA certification

- Perform seasonal maintenance checks on seals, drainage, and caulking

- Consider UV-filtering window films for added protection

Long-Term Protection Strategy

| Strategy Component | Recommended Action |

|---|---|

| Frame Material | reinforced aluminium |

| Glazing Type | Triple-pane, low-E, gas-filled |

| Installation Quality | CSA-certified professionals |

| Maintenance | Seasonal checklist and annual calendar |

| Additional Protection | UV film and exterior shading systems |

Final tips

- Photograph damage and document repairs for warranty and insurance

- Plan upgrades every 20–25 years, sooner in extreme climates

- Consult professionals for assessments before winter or summer peaks

1000’s of Colours & Textured Finishes

Transform your home from ordinary to extraordinary with our new coloured and non-glare textured finishes. Available in a wide array of colours as well as custom matched colours for your very own personalized design.

Our Most Popular Replacement Window Colours: