Comparing Window Hardware: Chinese vs North American Quality

Key Takeaways

- North American window hardware is built to rigorous safety and durability standards, while Chinese counterparts may follow different or less comprehensive protocols.

- Significant differences exist in certifications, materials, and design philosophies.

- Chinese hardware is typically lower in upfront cost, but it may have trade-offs in terms of quality and lifespan.

- Independent testing often reveals that North American hardware outperforms its counterparts in terms of longevity and corrosion resistance.

- Tariffs and shipping costs influence the actual cost of Chinese imports.

What are the key differences between Chinese and North American window hardware?

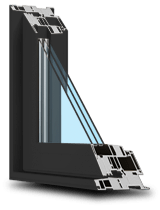

At first glance, window hardware from China and North America may look alike — they often operate similarly and fit comparable window systems. However, there are significant differences beneath the surface in design approach, materials used, and certification standards.

Design Standards and Certifications

North American manufacturers — especially those based in Canada and the United States — are bound by stringent regulatory frameworks. For instance, many follow CSA (Canadian Standards Association) and NFRC (National Fenestration Rating Council) guidelines. These standards ensure not only functionality but also long-term durability, energy efficiency, and safety.

In contrast, Chinese hardware is governed by domestic GB standards, which are often less comprehensive than international standards. While some premium Chinese manufacturers do certify their products for the North American market, many do not. The result can be varying levels of quality control across different product lines.

“We’ve seen a wide range in Chinese import quality,” says Tony Wong, Project Manager at Canadian Choice Windows & Doors™ . “Some perform just fine, but others fail basic lifecycle testing. You don’t know what you’re getting unless it’s certified.”

Materials and Manufacturing Quality

North American components tend to use aluminum alloys, stainless steel, and UV-resistant plastics engineered for harsh climates. For example, mechanisms are often made with higher-grade metals to resist corrosion and perform reliably over thousands of open and closed cycles.

On the other hand, Chinese hardware may utilize lower-cost zinc alloys, uncoated metals, and basic polymers. This makes them more affordable but susceptible to wear, rust, or UV damage over time.

Product Lifespan and Reliability

Longevity plays a key role. In standardized mechanical cycle tests (typically 20,000–25,000 open/close actions), North American products consistently pass or exceed benchmarks. Chinese imports, however, vary widely — some meet expectations, others show reduced performance after 8,000–12,000 cycles.

Comparison Table

| Feature | North American Hardware | Chinese Hardware |

|---|---|---|

| Design Standards | CSA, NFRC | GB (domestic Chinese) |

| Certification | Required for most installations | Optional or inconsistent |

| Primary Materials | Stainless steel, UV-grade polymers | Zinc alloys, basic plastics |

| Average Product Lifespan | 15–25 years | 5–12 years |

| Mechanical Cycle Test | 20,000+ cycles | 8,000–15,000 cycles |

| Corrosion Resistance | High | Moderate to low |

| Price | Higher | Lower |

| Warranty Coverage | 10–20 years | 1–5 years (if any) |

How does the price of Chinese window hardware compare to North American options?

It’s no secret that Chinese window hardware is priced lower. But what do those numbers actually mean in real-world terms — and do the savings justify the trade-offs?

Price Brackets and Cost Tiers

Basic North American window hardware components (like locks, handles, and hinges) typically range between $20-$60 per unit, depending on the manufacturer and material. In contrast, comparable Chinese imports cost between $5 and $25 per unit.

However, that initial saving doesn’t tell the whole story.

Value vs. Long-Term Cost

Here’s the catch: installation, warranty claims, and replacements all add up. When hardware wears out too soon, you end up spending more in the long run. A low-cost unit replaced twice within ten years may end up costing more than a reliable one that only needs replacement once in 20 years.

Tariffs and Import Impact

With tariffs in place, the actual landed cost of Chinese hardware includes:

- Import duties (up to 25%)

- Ocean freight charges

- Customs clearance fees

- Time delays or logistics disruptions

Is there a difference in durability between Chinese and North American window hardware?

Durability is arguably the most critical metric for window hardware, especially in climates like Canada’s, where seasonal extremes test materials year-round.

Corrosion and Climate Resistance

Salt spray tests, which simulate years of outdoor exposure, favour North American hardware with anti-corrosion coatings and stainless steel mechanisms. In accelerated tests, Chinese parts without protective finishes showed signs of rusting significantly sooner.

Material Deformation and UV Impact

Cold winters and hot summers can cause materials to expand, warp, or crack. North American products are often tested for thermal cycling to simulate these shifts, while many Chinese imports skip this testing or underperform when exposed to temperature extremes.

Summary Table: Durability Metrics

| Durability Factor | North American Hardware | Chinese Hardware |

|---|---|---|

| Mechanical Cycles | 20,000–30,000+ | 8,000–15,000 |

| Salt Spray Resistance | 500–1,000 hours | 100–300 hours |

| UV Resistance | High (UV-stabilized plastics) | Variable, often low |

| Thermal Cycling Tested | Yes | Often not |

| Common Failure Points | Minimal | Handles, hinges, and surface rust |

Are Chinese window hardware products certified in Canada?

Certification is one of the key sticking points for Chinese imports entering the Canadian market. So, can you trust that imported hardware meets local standards? The short answer: only if it's CSA-certified.

Canadian Building Code and Certification Requirements

According to the National Building Code of Canada (NBCC), any component used in residential construction — especially those involving fire, egress, or security — must meet recognized performance standards. This includes:

- CSA A440 standards for windows and hardware

- Energy efficiency requirements (if the hardware affects sealing or insulation)

- Safety requirements (especially for locking mechanisms)

Warranty and Safety Implications

Even if the hardware functions properly, uncertified products can void warranty, especially with Canadian or U.S. manufacturers. This risk becomes critical in resale scenarios or insurance claims.

Industry and Forum Feedback

Window industry forums, such as GreenBuildingAdvisor and RedFlagDeals, regularly discuss the pitfalls of uncertified imports. Common themes include:

- Fitment issues with Canadian window frames

- Lack of support from manufacturers

- Frequent early failures in locking systems

Does window hardware really affect the energy efficiency of your windows?

We often focus on glass or insulation when thinking about window energy efficiency, but the hardware also matters just as much for ensuring everything seals tightly. Poor-quality parts can undermine even the best triple-glazed windows.

Locking Mechanisms and Thermal Seals

Good hardware creates even compression across the window frame, which helps the seals perform properly. Weak or misaligned locks might lead to air leakage and reduced insulation.

Compression Lock Force

In lab conditions, compression locks must apply enough force to depress the weather stripping by 50–60%. Cheap components often fall short of this mark, especially after they have been subjected to wear and tear.

Practical Impacts

- Increased heat loss through air gaps

- Condensation build-up from poor sealing

- Reduced soundproofing from incomplete closures

In short, even small hardware parts have a significant impact on the overall energy profile of your home.

Can you mix and match Chinese and North American hardware in one home?

It may seem like a good idea to mix lower-cost Chinese parts with North American hardware. Still, this combination can lead to technical problems and design clashes that homeowners should be aware of before installation.

Compatibility Issues

North American windows and frames are manufactured to standard specifications in accordance with CSA guidelines. Hardware components such as locks, hinges, and cranks must match these dimensions precisely to function correctly.

Chinese hardware, on the other hand, often follows different spacing for mounting holes, metric fasteners, and unique gear ratios for mechanisms. As a result:

- Cranks may not align with the window gears

- Locks may interfere with sash movement

- Hinges may limit the opening angle

Aesthetic Mismatch

- North American hardware often features neutral tones, such as brushed nickel, matte black, or oil-rubbed bronze, with a modern design aesthetic.

- Chinese parts may come with chrome, gold plating, or plastic finishes that do not always align with typical North American design preferences.

While mixing is technically possible, it risks a disjointed visual presentation, especially when replacing only part of a window system.

Compatibility Table

| Feature | North American Hardware | Chinese Hardware | Mixing Considerations |

|---|---|---|---|

| Mounting Spacing | CSA Standard | Variable (metric) | May need redrilling or spacers |

| Finish Style | Matte, brushed, neutral tones | Glossy finishes with metallic hues | Visible mismatch in tone/design |

| Weight and Material | Balanced, tested | May vary by batch | Can strain hinges or joints |

| Screw Thread Type | Imperial (US) | Metric | May strip or misalign fasteners |

| Operating Geometry | Standard | Custom | Requires test-fit before final install |

Final Thoughts: What Window Hardware is Best for Canadian Homes?

Choosing between Chinese and North American window hardware ultimately depends on your priorities, including cost, performance, longevity, and certification. But when it comes to long-term investment, for long-term performance and certification assurance, North American products are generally preferred.

Summary Table: Regional Comparison

| Feature | North American Hardware | Chinese Hardware |

|---|---|---|

| Certification | CSA, NFRC, WDMA | GB (some with CSA equivalents) |

| Corrosion Resistance | High | Moderate to low |

| Material Durability | Stainless steel, UV polymers | Zinc, basic plastics |

| Installation Ease | Designed for CSA frames | May require modification |

| Warranty and Support | 10–20 years | 1–5 years (often limited) |

| Price | Higher upfront cost | Lower initial cost |

| Energy Efficiency Impact | Certified compression locks | Variable, often poor |

Buyer Tips

- Check for CSA certification before purchase

- Avoid unbranded imports, especially online

- Compare warranties — short terms can signal low quality

- Don’t mix systems unless you consult a qualified installer

- Invest in quality hardware if you live in coastal or extreme climates

Sources Used

- CSA Group: Window and Door Certification

- WDMA Performance Guidelines

- Journal of Building Physics Studies on Compression Locks

- AAMA Lifecycle Cost Studies

- Green Building Advisor Forums

1000’s of Colours & Textured Finishes

Transform your home from ordinary to extraordinary with our new coloured and non-glare textured finishes. Available in a wide array of colours as well as custom matched colours for your very own personalized design.

Our Most Popular Replacement Window Colours: