Windows and Doors in Passive Houses: Key Features and Requirements

Key Takeaways

- A passive house is a building standard that focuses on maximizing energy efficiency, ensuring indoor comfort, and minimizing its ecological footprint.

- Use triple glazing, low-E coatings, and airtight frames (uPVC, fibreglass).

- Must meet U-value ≤ 0.80 W/m²K and airtightness ≤ 0.6 ACH per Passive House Institute and PHIUS standards.

- Provide draft-free comfort, quiet interiors, and clean indoor air.

- Doors feature multi-point locks and reinforced, insulated cores for security.

- Retrofits are possible, cutting heating demand by over 50%.

- Pay back in about 10 years through energy savings and higher resale value.

- Support Canada’s 2050 net-zero emissions goal and future-ready housing.

What is a passive house, and why is it important?

A passive house is designed to stay warm in winter and cool in summer while using minimal energy. That’s the core idea of a passive house.

Defining the Passive House Standard

A passive house (or Passivhaus , originating from Germany) refers to a voluntary building standard for energy efficiency. It's not a brand or product — it's a strict performance-based benchmark. According to the Passive House Institute, a building must meet the following criteria to qualify:

- Annual heating demand: ≤15 kWh/m2

- Primary energy demand: ≤120 kWh/m2

- Airtightness: ≤0.6 ACH (air changes per hour) at 50 Pa

This is achieved through thoughtful design that minimizes energy demand from the start.

Benefits: Energy Efficiency and Air Quality

Passive homes consume up to 90% less energy for heating and cooling compared to traditional buildings. According to Natural Resources Canada , space heating accounts for over 60% of residential energy use in the country. Passive design slashes that demand.

But energy savings are only part of the story:

- Healthier indoor air thanks to mechanical ventilation with heat recovery (HRV)

- Consistent temperatures and no cold spots

- Superior noise reduction from airtight construction

- Smaller HVAC systems reduce maintenance and upfront cost.

Tony Wong, Project Manager в Canadian Choice Windows & Doors :

"Passive House design requires a fundamental shift in how we approach building efficiency. It’s not simply about adding more insulation — it’s about integrating advanced window and door systems to eliminate thermal weak points and achieve consistent energy performance throughout the building envelope."

How do passive house windows differ from regular energy-efficient windows?

Windows in Passive House buildings are designed to perform much better than standard windows. Let’s compare them.

Key Differences Explained

| Feature | Passive House Windows | Standard Energy-Efficient Windows |

|---|---|---|

| U-value (thermal transmittance) | ≤ 0.80 W/m2K | 1.2 – 1.8 W/m2K typical |

| Glazing | Triple-pane with argon/krypton fill | Double or triple-pane with air/argon |

| Airtightness | Fully sealed, test below 0.6 ACH | Variable, not always tested |

| Frame design | Multi-chambered, insulated | Standard vinyl or aluminum |

| Spacer technology | Warm edge, non-metallic | Often metal spacers |

| Solar heat gain coefficient (SHGC) | Tuned for orientation | Often fixed or average |

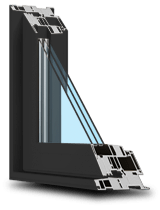

Construction and Performance

Passive-certified windows must meet EN or PHI standards (e.g., those set by the Passive House Institute). Their frame systems often include:

- Thermal breaks to prevent heat bridging

- Multi-point locking for tighter seals

- Low-emissivity (low-E) coatings to reflect heat

- Warm-edge spacers to reduce condensation risk

These features ensure thermal performance that complements the building envelope, rather than competing with it.

What materials are used in passive house windows and doors?

Frame Materials

Not all materials perform equally. Passive house frames must be thermally broken and ultra-durable.

-

uPVC (unplasticized polyvinyl chloride)

:

- Excellent insulation

- Affordable and low-maintenance

- Can be reinforced with steel or fibreglass

-

Fiberglass

:

- Very low thermal expansion

- Strong and dimensionally stable

- Excellent for larger window spans

-

Wood (often with aluminum cladding)

:

- Natural insulation

- Aesthetic value

- Requires more maintenance unless clad

Glass Types and Coatings

Glass in passive-certified windows is multi-functional:

- Triple glazing is standard, not optional

- Low-E coatings control solar gain.

- Gas fills (such as argon or krypton) increase insulation.

- Laminated glass can be used for both acoustical and safety purposes.

Spacer and Seal Technologies

- Warm edge spacers made of plastic or composite materials

- Dual or triple seals for airtightness

- Compression gaskets to reduce sound and air leakage

Here’s a quick summary table of key materials and their performance:

| Component | Preferred Material | Reason |

|---|---|---|

| Frame | Fibreglass / uPVC | Low conductivity, strength |

| Glazing | Triple-pane w/ Low-E | Energy retention |

| Spacer | Warm edge (non-metal) | Prevents condensation |

| Sealant | EPDM or silicone gaskets | Airtight, durable |

Closing Thoughts on Materials

The passive standard is about systems, not just individual features. All parts — frames, glazing, spacers, and seals — work together to ensure the window or door doesn’t compromise the building envelope.

And while these components may cost more upfront, long-term energy savings, durability, and comfort often make them a worthwhile investment.

Are passive house doors truly airtight and secure?

At first glance, passive house doors may look like regular entry doors — but the similarities stop there. These doors are meticulously engineered to meet airtightness and insulation benchmarks that align with the passive house standard.

Design Features That Ensure Airtightness

- Multi-point locking systems : These locks pull the door tightly against the frame at several points, not just at the latch. This eliminates air gaps and warping.

- Thick, insulated cores : Passive doors often have insulated cores made from polyurethane or cork-based composites, achieving U-values as low as 0.6 W/m²K.

- Continuous perimeter seals : Flexible yet durable gaskets around the door leaf ensure a consistent air barrier.

- Heavy-duty hinges and compression handles : These ensure precise alignment and maximum pressure on seals.

Security Without Compromise

Passive house doors meet or exceed security expectations due to:

- Reinforced lock zones

- Tamper-resistant hardware

- Laminated or multi-layer glass in glazed units

And the airtight construction has a side benefit: doors are nearly impossible to pry open without significant noise and effort.

Passive Door vs. Standard Entry Door

| Feature | Passive House Door | Standard Exterior Door |

|---|---|---|

| U-value | ≤ 0.8 W/m²K | 1.6–2.0 W/m²K |

| Locking System | Multi-point | Single-point |

| Seal Quality | Triple-sealed, continuous | Single or double gasket |

| Insulation Core | PU foam/cork / wood fibre | Foam or hollow-core |

| Air Infiltration | ≤0.6 ACH at 50 Pa | Not always rated |

How do passive house windows improve energy efficiency?

When discussing energy efficiency, windows are often the weakest point in a building's envelope. Passive house windows address this challenge through advanced design and optimized performance.

Thermal Insulation and U-Values

Windows in passive houses must achieve a U-value of below 0.8 W/m²K. This reduces thermal transfer, keeping warmth in during winter and out during summer.

- Triple glazing and gas-filled cavities act like insulated walls.

- Low-E coatings reflect infrared heat, maintaining stable indoor temperatures.

- Thermal breaks in frames prevent heat transfer through conduction.

Solar Heat Gain and Energy Modelling

Designing for solar heat gain (SHG) is another crucial factor. South-facing windows can act as passive solar collectors in winter, reducing heating loads.

Energy modelling software like PHPP (Passive House Planning Package) is used to optimize:

- Window size and placement

- Glazing types and coatings

- SHGC (solar heat gain coefficient)

As Helen Sin says:

High-performance windows contribute not only to lower energy costs but also to a consistently comfortable indoor environment, even when heating systems are not in use."

Can passive house-certified products be retrofitted into existing homes?

You don’t need a brand-new build to benefit from passive performance. While challenging, retrofitting passive-certified windows and doors into existing homes is becoming increasingly common — and increasingly worthwhile.

Step-by-Step Retrofit Guide

-

Assessment

:

- Perform a blower door test to assess air leakage.

- Evaluate window and door openings for depth and structural integrity.

-

Product selection

:

- Select certified products that fit existing frames or require minimal structural adjustments.

- Match SHGC values to your local solar exposure.

-

Installation

:

- Use airtight installation techniques: membranes, tapes, and insulated shims.

- Install windows and doors in the insulation layer of the wall.

-

Sealing and testing

:

- Re-do the blower door test to measure improvement

- Use infrared thermography to locate remaining leaks.

Challenges

- Some homes lack sufficient wall thickness.

- Costs can be high without government incentives.

- Requires careful installation to avoid moisture issues

Benefits

- Improved comfort and energy savings

- Noise reduction in urban areas

- Increased property value and resale appeal

How are passive house windows and doors certified?

Passive house components — particularly windows and doors — aren’t just marketed as “efficient.” They must be tested, verified, and certified by recognized organizations. The two leading authorities are:

1. Passive House Institute (PHI)

Based in Germany, PHI developed the original passive house standard. Products certified by PHI go through rigorous testing against the following:

-

Thermal transmittance (U-value)

:

- Windows must achieve U ≤ 0.80 W/m²K overall

- Doors must achieve U ≤ 0.80–1.0 W/m²K, depending on application

-

Airtightness

:

- Measured via blower door tests to ensure minimal leakage

-

Solar heat gain coefficient (SHGC)

:

- Optimized by orientation and building energy modelling

-

Edge losses and frame insulation

:

- Thermal bridge-free design and high PSI (Ψ) values

2. Passive House Institute US (PHIUS)

PHIUS certifies products for North America's specific climate zones. The criteria are similar, but adapted for varied weather extremes, especially in Canada.

- Regionalized U-value limits based on climate zone (cold vs mixed)

- Condensation resistance testing for Canadian winters

- Third-party lab verification required

Required Testing and Evaluation

Certification involves more than just lab tests. Manufacturers must submit:

- Detailed component specs (frame, glazing, seals)

- Installation manuals for airtight installation

- Simulation data from software like WUFI Passive or PHPP

Products are listed in the Certified Component Database on passivehouse.com and phius.org.

Certification Table

| Certification Body | Region | U-Value Limit | Airtightness | Other Criteria |

|---|---|---|---|---|

| PHI (Germany) | Global | ≤ 0.80 W/m²K | ≤ 0.6 ACH | SHGC, PSI values |

| PHIUS (USA/Canada) | North America | Zone-specific | ≤ 0.6 ACH | Moisture, condensation,and install guides |

Why This Matters

Certification isn’t just a stamp — it ensures the product will perform as part of a complete passive house system. This gives homeowners peace of mind and helps meet Canada’s climate goals.

How much do passive house windows and doors cost in Canada?

In terms of cost, Passive House windows and doors in Canada typically come with a premium — but it’s not as steep as many assume.

Average Cost Ranges

| Product Type | Standard Range | Passive House Certified |

| Triple-glazed window (per unit) | $800 – $1,200 | $1,200 – $2,000 |

| Entry door system | $1,000 – $1,800 | $2,000 – $4,500 |

| Patio/sliding door | $1,200 – $2,000 | $2,500 – $5,000 |

Source : Pricing compiled from Canadian suppliers, Passive Design Solutions, and Efficiency Canada.

What Drives the Cost?

- Certification and testing: Adds production and compliance costs

- High-spec materials: Triple glazing, insulated cores, non-metal spacers

- Installation complexity: Passive units require a precise airtight installation

- Low-volume production: Fewer manufacturers = less price competition

Cost vs Value

While upfront costs can be 30–60% higher, the long-term savings are substantial:

- Energy bills drop 50–90% with full passive upgrades

- Increased home resale value, especially in green-conscious markets

- Government rebates: Programs like Canada Greener Homes Grant can offset up to $5,000

Regional Price Variability

Costs vary based on province, labour rates, and availability. In BC or Ontario, where passive design is more common, pricing is slightly more competitive than in the Prairies or Atlantic Canada.

Is the investment in passive house windows worth it for new builds?

New construction presents the perfect opportunity to go all-in on energy performance. But is it financially justified? Let’s break it down.

Upfront Costs vs Long-Term Gains

Installing passive-certified windows in a new build may increase window-related costs by 30%–60% compared to standard options. But that cost is often offset within a decade through:

- Lower energy bills

- Reduced HVAC sizing (smaller furnaces and AC systems)

- Fewer repair and maintenance needs

Comfort & Health Benefits

- No cold zones or radiant chill near windows

- Reduced allergens thanks to controlled ventilation

- Quieter interiors due to airtight sealing

Final Thought

If you’re already building new, integrating passive windows from day one is the most cost-effective way to do it: the same installation team, same design phase — just smarter component choices.

Are passive house windows and doors the future of home design?

Let’s recap what we’ve learned — and what it means for homeowners, builders, and architects in Canada.

Passive vs Traditional Windows & Doors

| Feature | Standard Product | Passive-Certified Product |

|---|---|---|

| Glazing | Double or triple | Triple with gas fill + Low-E |

| U-Value | 1.4–2.0 W/m²K | ≤ 0.80 W/m²K |

| Airtightness | Moderate | Extreme (≤ 0.6 ACH) |

| Cost | Lower upfront | Higher upfront, long-term savings |

| Energy Performance | Good | Excellent |

| Comfort | Standard | Exceptional |

Are Passive House windows and doors the future of Canadian home design?

With Canada’s 2050 net-zero emissions target and extreme winter conditions, passive house components offer a clear path forward. They deliver comfort, durability, and measurable savings.

They are not just a premium option — they represent a practical way to future-proof Canadian homes.

1000’s of Colours & Textured Finishes

Transform your home from ordinary to extraordinary with our new coloured and non-glare textured finishes. Available in a wide array of colours as well as custom matched colours for your very own personalized design.

Our Most Popular Replacement Window Colours: