How to Choose Fire-Rated Doors for Enhanced Home Safety

Key Takeaways

- Fire-rated doors are designed to resist fire and smoke for specified periods (20, 45, 60, or 90 minutes), helping to contain fires within a structure.

- These doors are constructed with materials such as steel, gypsum, or a mineral core, and differ significantly from regular wood or hollow-core doors.

- Ratings are certified through standard testing methods and are part of building code requirements in many residential and commercial applications.

- Fire-rated doors are not the same as "fireproof" doors — which is a common misconception.

- Selecting the right fire-rated door can enhance home safety, ensure code compliance, and impact insurance eligibility.

What exactly is a fire-rated door, and how does it work?

Fire-rated doors may resemble regular, heavy-duty doors, but their internal structure is engineered to resist fire and smoke for a specified period. Fire-rated doors are designed to withstand high temperatures and slow down the spread of flames and smoke for a specific duration, often giving building occupants and first responders crucial time to act.

What is a fire-rated door?

A fire-rated door is a specialized door assembly, including the frame, hardware, and seals, that has been tested and certified to resist fire for a specific time period under laboratory-controlled conditions. These doors are not entirely fireproof (no material truly is), but they're engineered to hold back flames and smoke based on their fire-resistance rating.

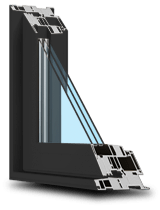

Construction: What are they made of?

Fire-rated doors differ from regular doors mainly due to their core materials and structural reinforcements. Here's a breakdown of typical construction:

- Core Material : Often includes steel, gypsum , or mineral core — all of which offer excellent heat resistance.

- Steel Skins : Many fire-rated doors utilize steel facings for enhanced durability and added protection.

- Honeycomb or Composite Core : Some residential models utilize composite materials with intumescent seals that expand upon exposure to heat.

- Fire-Rated Glass : If a window is included in the door, it must be wired or ceramic glass rated for fire exposure.

Fire-rated doors are usually heavier and thicker than standard interior or exterior doors, with intumescent seals that expand during a fire to block smoke and flames from spreading through gaps.

Understanding the Rating System

Fire-rated doors in Canada are evaluated using standardized fire testing procedures, typically referencing CAN/ULC-S104 (Canadian standards) or NFPA 252 (U.S. equivalent).

They’re classified by how long they can contain a fire:

| Rating (Minutes) | Application | Notes |

|---|---|---|

| 20 | Interior residential units (condos) | Often used in suite entries |

| 45 | Commercial and some residential areas | Moderate fire risk zones |

| 60 | Common corridors, mechanical rooms | Increased risk or code requirement |

| 90 | Attached garages, storage, utility rooms | Maximum residential protection |

These time ratings don’t mean the door disintegrates after the time limit — they define how long it can effectively resist fire exposure under test conditions before it fails structurally.

How they differ from regular doors

Your standard interior door (e.g., hollow-core MDF or wood) provides no fire resistance. In fact, they can become fuel for a fire, contributing to the rapid spread of flames. Fire-rated doors, in contrast:

- Use non-combustible materials

- Feature certified construction

- Have labelled ratings

- Include fire-resistant hardware and seals.

In short, they’re engineered safety devices, not just barriers.

“Choosing the right fire-rated door ensures compliance with building codes and provides essential protection for occupants.”

— Helen Sin , Consumer Success Manager, Canadian Choice Windows & Doors

What materials are commonly used in fire-rated interior doors in Canada?

Fire-rated interior doors in Canada are constructed with materials specifically chosen to delay combustion, reduce thermal transfer, and resist structural degradation in the presence of heat. While many consumers associate “metal” with “fire-rated,” a variety of core and surface materials are used, depending on the desired rating, location, and aesthetic.

Common Materials Used

-

Solid Core Wood (Particleboard or Mineral Core)

- Often found in 20-minute rated doors.

- Used primarily in residential interiors where lower fire risk is assumed.

- Includes intumescent seals along the frame.

-

Steel-Clad Doors

- Usually rated from 45 to 90 minutes.

- Feature steel face panels with a gypsum or mineral core.

- Preferred in multi-family housing, utility rooms, or entry points from garages.

-

Composite Core Doors

- Combine engineered wood, high-density fiberboard, and non-combustible cores.

- Available in a wide range of finishes.

- Can include veneer overlays for aesthetics.

-

Pressed Metal Frames

- Typically used with steel fire doors.

- Designed to hold up under fire stress without warping.

-

Glass or Vision Panels

- Must be fire-rated glass (wired or ceramic).

- Never used in wood-core doors unless explicitly tested and certified.

Specification Table

| Material Type | Typical Fire Rating | Application Area | Notable Features |

|---|---|---|---|

| Solid Core Wood | 20 min | Bedrooms, hallway doors | Affordable, basic protection |

| Steel with Gypsum | 45–90 min | Entry to garages, mechanical rooms | Durable, code-compliant |

| Composite Core | 20–60 min | Custom interiors, main floors | Customizable, aesthetic flexibility |

| Fire-rated Glass Panel | 20–45 min | Doors with visibility needs | Requires certified glass + framing |

Canadian Manufacturing Standards

Fire-rated doors in Canada must comply with CAN/ULC-S104, the primary standard governing fire tests of door assemblies. Certification agencies like ULC, Intertek, and Warnock Hersey (WH) audit and certify both manufacturers and the individual door products.

To be installed legally in Canada, a door must:

- Be tested to CAN/ULC-S104.

- Display a certification label or metal tag identifying the rating and certifying agency.

- It is installed as a complete assembly, including the door, frame, hinges, and seals.

“Without proper testing and labelling, a steel door cannot be considered fire-rated. Verified certification is essential.”

— Tony Wong , Project Manager, Canadian Choice Windows & Doors

What certifications and ratings should you look for in a fire-rated door?

Buying a fire-rated door isn’t just about thickness or material — it’s about certified compliance with rigorous testing standards. In Canada, several agencies certify and label doors to ensure they meet the required fire-resistance levels.

Key Certification Labels

-

ULC (Underwriters Laboratories of Canada)

- Recognized Canadian authority.

- The label includes a rating (e.g., 45 minutes) and a unique serial number.

- Often accompanied by CAN/ULC-S104 test standard.

-

WH (Warnock Hersey)

- A division of Intertek.

- Common in North American doors, especially those imported from abroad.

- The label includes the WH logo, fire-resistance rating, and certification agency.

-

Intertek

- Tests and certifies globally.

- Recognized in both residential and commercial builds.

How to Read Fire Door Labels

Look for a metal plate or permanent label affixed to the hinge side or top of the door. It should include:

- Fire rating time (e.g., 45 MIN, 90 MIN)

- Testing standard (e.g., CAN/ULC-S104 or NFPA 252)

- Certifying agency logo (e.g., ULC, WH, Intertek)

- Unique ID or serial number for tracking

If the door has a vision panel or window, it must be marked separately with its own certification for the glass.

Canadian Regulations

In residential applications, Canadian Building Codes often require:

- 20-minute rated doors for condo suite entries.

- 60-90 minute-rated doors for entries from garages or mechanical rooms.

- Full compliance with CAN/ULC-S104.

🔗 For detailed code requirements, refer to the National Building Code of Canada (NBC) .

Step-by-Step Certification Check

- Locate and read the label or tag.

- Confirm the fire rating and standard.

- Check the certifying body (e.g., ULC, WH, etc.).

- Verify that the installation method matches the certified specifications.

- If in doubt, consult the manufacturer’s certification listing online.

Can fire-rated doors also include windows or glass panels?

Yes — but only under particular conditions. Fire-rated doors can include vision panels made from special fire-resistant glass, but standard glass is never acceptable.

What Types of Glass Are Used?

-

Wired Glass

- Embedded metal mesh for strength.

- Holds shape under pressure or cracking.

- Used for 20–45 minute ratings.

-

Ceramic Glass

- Transparent and high-temperature resistant.

- Withstands thermal shock.

- Found in 60–90 minute rated assemblies.

-

Fire-Rated Glass with Intumescent Layer

- Swells under heat, blocking flames and smoke.

- Requires special framing systems.

Safety & Legal Considerations

- Glass must be listed on the door’s certification label.

- The frame and mounting for the glass must also be tested and certified.

- Maximum glass area is often restricted — typically less than 100 square inches for high-rated doors.

- Larger panels require tested glazing systems.

Specification Table

| Glass Type | Fire Rating Capacity | Use Cases | Safety Notes |

|---|---|---|---|

| Wired Glass | Up to 45 minutes | Offices, corridor doors | Strong but limited in visual clarity |

| Ceramic Glass | Up to 90 minutes | Garage entries, stairwells | High cost, excellent performance |

| Intumescent-Layer Glass | 60–90 minutes | Schools, institutional buildings | Must be part of a certified system |

What are the key features of a high-quality fire-rated door?

A high-quality fire-rated door doesn’t just rely on core materials — it functions as a complete system, where every component contributes to fire protection. Whether you're buying for a home, condo, or garage entry, certain features signal higher quality and compliance.

1. Intumescent Strips

- Heat-activated seals that expand when exposed to fire.

- Installed around the frame or edges.

- They block smoke, toxic gases, and flames from passing through gaps.

2. Self-Closing Mechanisms

- All rated fire doors must automatically close without manual input.

-

This is usually achieved via:

- Surface-mounted door closers

- Spring hinges

- Concealed automatic closers

3. Smoke Seals

- Some doors include additional cold smoke seals.

- Designed to stop smoke at lower temperatures before intumescent activation.

4. Fire-Rated Frames

- The door must be installed in a fire-rated frame made of metal or certified wood.

- The frame should match the rating of the door.

5. Labelling and Certification

- High-quality doors feature permanent metal labels or plates.

- Includes certifying body, rating (in minutes), and standard used (e.g., CAN/ULC-S104).

Specification Table

| Feature | Importance | Notes |

|---|---|---|

| Intumescent Strips | Expands in heat to seal door gaps | Required for >20-minute ratings |

| Self-Closing Mechanism | Ensures the door closes after opening | Mandatory in all fire-rated systems |

| Smoke Seals | Blocks cold smoke before heat triggers strips | Often required in high-rise installations |

| Rated Door Frame | Prevents fire penetration around edges | Must match or exceed the door's rating |

| Certification Label | Confirms fire test compliance | Look for ULC, WH, or Intertek |

How do Canadian fire safety codes influence fire-rated door requirements?

Fire-rated doors are not optional — in many cases, they are a legal requirement under Canadian building codes. In both new construction and renovations, local codes dictate when, where, and what type of fire-rated door must be installed.

National Building Code of Canada (NBCC)

The NBCC sets minimum requirements for fire protection in buildings. Section 3.1 outlines the required fire separations and fire-resistant components.

Key residential applications include:

- Doors between garages and living spaces — must be 45- or 90-minute rated.

- Apartment or condo entry doors — typically rated for 20 minutes.

- Furnace and mechanical rooms may require a 60-minute rating, depending on the location.

Provincial and Municipal Variations

While the NBCC sets the baseline, each province and territory can enforce variations:

- Ontario follows the Ontario Building Code, which mirrors NBCC but with tighter rules for high-rise buildings.

- British Columbia applies its BC Building Code, which includes specific regulations for suite separation in multi-family dwellings.

Local bylaws may also dictate:

- When smoke seals or closers are mandatory.

- Retrofit requirements for older buildings.

- Firestop systems around door penetrations.

Certification Requirements

To be compliant, a fire-rated door must:

- Be tested to CAN/ULC-S104.

- Display a visible label or tag.

- Be installed as a whole, certified assembly.

Failure to comply can lead to:

- Building inspection failures

- Insurance claim rejections

- Increased liability during fire-related incidents

What’s the best way to choose a fire-rated door for your home?

In fire safety, a certified door functions as part of a complete protection system, ensuring compliance with Canadian codes and safeguarding the integrity of your home. Here’s how to make the best choice.

Types and Use Cases

| Door Type | Best Use Case | Rating Needed | Key Feature |

|---|---|---|---|

| Solid Core Wood | Bedroom doors, low-risk zones | 20 minutes | Budget-friendly basic protection |

| Steel Door with Gypsum | Garage entry, furnace rooms | 45–90 minutes | High durability + resistance |

| Composite with Veneer | Custom interiors, modern homes | 20–60 minutes | Style + certified safety |

| Glass-Panel Fire Door | Office or main floor entry visibility | 20–45 minutes | Certified fire glass, aesthetic |

Final Advice

- Review your home's layout and identify areas that are higher risk.

- Select doors that meet or exceed the minimum code requirements.

- Ensure full system compatibility — door, frame, hardware, seals.

- Buy from manufacturers offering verified certifications.

- Budget for professional installation and inspection.

Sources Used:

- National Building Code of Canada — nrc.canada.ca

- Intertek Certification Overview — intertek.com

- ULC Standards — canada.ul.com

1000’s of Colours & Textured Finishes

Transform your home from ordinary to extraordinary with our new coloured and non-glare textured finishes. Available in a wide array of colours as well as custom matched colours for your very own personalized design.

Our Most Popular Replacement Window Colours: