Insulated glass and Low-E glass: how they work together in modern windows

Modern Canadian windows are built as layered systems, designed to perform in real Canadian conditions, not just in controlled testing. The insulated glass unit (IGU) provides the sealed, multi-pane structure, while Low-E coatings fine-tune how the glass handles radiant heat and sunlight.

Together, these layers improve year-round comfort, support energy efficiency, and help protect interiors from UV exposure. Natural Resources Canada notes that Low-E coatings can reduce winter heat loss and summer heat gain by up to 50% in some cases.

This guide explains how IGUs and Low-E work inside the same window assembly, what to look for on Canadian performance labels, and how to choose a configuration that matches your home’s exposure, climate, and comfort priorities — without guesswork.

Key takeaways

- Insulated glass (an IGU) is a sealed, multi-pane unit designed to slow heat transfer using spacing, gas fills, and airtight seals.

- Low-E glass refers to a near-invisible coating applied to the inside of a glass surface within the unit to manage radiant heat and solar heat gain.

- In most modern Canadian windows, Low-E coatings are specified as part of the insulated glass unit, alongside spacers and gas fills.

- Real-world performance comes from the full system working together: glazing, frames, and installation details, not from a single specification in isolation. This benefit-led approach focuses on everyday comfort, durability, and long-term performance in real homes.

Why Window Glass Specs Matter in Canada

Canadian homes see wide temperature swings, wind exposure, and long heating seasons in many regions. Windows sit at the boundary between indoor comfort and outdoor conditions, so glazing choices influence more than just energy bills. They affect cold spots near windows, condensation behaviour, glare, fading on floors and furniture, and the stability of your indoor temperature throughout the day.

For homeowners comparing options, it helps to frame insulated glass and Low-E as two layers within a modern window system:

- Insulated glass unit (IGU): the sealed multi-pane assembly that slows heat transfer through the structure and insulating gaps.

- Low-E coating: a performance layer on a glass surface inside the IGU that controls radiant heat and solar behaviour.

That combination is common in ENERGY STAR-qualified window configurations used across Canadian climate zones .

Insulated Glass Units (IGUs): Structure and Purpose

Insulated glass, often called an insulated glass unit (IGU), is made of 2 or 3 panes separated by a spacer and sealed into a single unit. The gap between panes is commonly filled with an inert gas such as argon or krypton, which conducts heat less effectively than regular air. The unit is sealed to keep moisture out and maintain the gas fill over time.

This structure improves comfort by reducing the rate at which indoor heat escapes in winter and by slowing heat entry in summer.

IGU components and what they do

| IGU component | What it is | What it does for the home |

|---|---|---|

| Glass panes (double or triple) | Multiple layers of glass | Helps reduce heat transfer and improves indoor stability |

| Spacer system | Material that keeps panes separated | Maintains the insulating gap and impacts edge performance |

| Gas fill (argon or krypton) | Inert gas inside the gap | Increases insulating value compared to air-filled gaps |

| Seal system | Primary and secondary seals | Keeps moisture out and helps retain gas fill over time |

Common IGU configurations in Canadian homes

| Configuration | Typical use case | Homeowner benefit |

|---|---|---|

| Double pane (2 panes) | Many modern replacement projects | Solid comfort upgrade over older windows |

| Triple pane (3 panes) | Colder regions, comfort-first upgrades | Better interior glass temperature and reduced cold spots |

| Gas-filled IGU | Common in energy-focused builds | Improved insulation and comfort consistency |

Low-E coatings: Function and Benefits

Low-E stands for low emissivity. It refers to a microscopically thin coating applied to a glass surface. It is designed to reduce radiant heat transfer while allowing visible light to pass through. Depending on the coating type and its placement within the sealed unit, Low-E can support winter heat retention and summer solar control.

Natural Resources Canada describes Low-E coatings as a key window feature and notes they can reduce winter heat loss and summer heat gain by up to 50% in some cases.

Where the Low-E coating Sits in the Window

Low-E is typically applied to an interior-facing surface within the sealed IGU, protecting it from cleaning, scratches, and weather exposure. Placement matters because it affects how the coating interacts with indoor heat and outdoor sunlight.

Low-E Coating Types in Plain Terms

| Coating type | How it is made | Typical traits |

|---|---|---|

| Hard coat (pyrolytic) | Applied during glass manufacturing | Durable, often used in certain cold-climate applications |

| Soft coat (sputtered) | Applied after the glass is formed | Higher energy performance is common in high-efficiency builds |

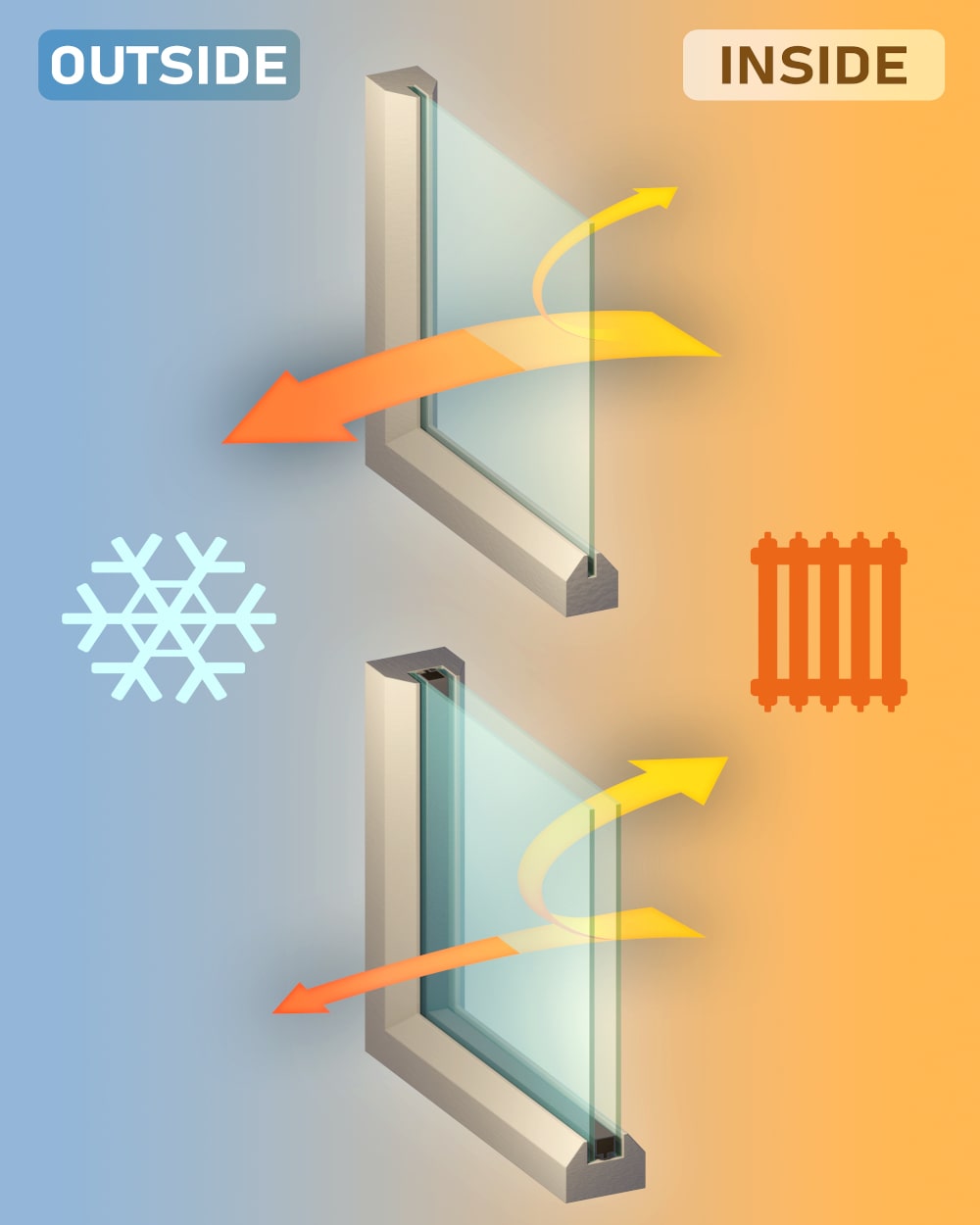

How do Insulated Glass and Low-E Support Comfort Together

Insulated glass and Low-E improve window performance in different ways. A useful way to explain this without overloading the reader is to tie each layer to the main modes of heat transfer.

Heat transfer through windows: what each layer addresses

| Heat transfer mode | What it means | How the IGU helps | How Low-E helps |

|---|---|---|---|

| Conduction | Heat moving through materials | Multiple panes plus insulating gaps slow heat flow | Indirect benefit by stabilizing the glass surface temperature |

| Convection | Heat moving through air or gas | Sealed gaps reduce air movement, and gas fill improves resistance | Indirect benefit through reduced radiant exchange |

| Radiation | Heat moves as infrared energy | Pane layering helps somewhat | Coating reflects infrared energy to manage radiant heat and solar effects |

This is why modern Canadian windows are typically specified as a layered system. When the layers work together, rooms tend to feel more even throughout the day, with fewer cold spots in winter and less overheating during strong sun exposure.

What to look for on Canadian Energy Labels

Homeowners often see multiple numbers and acronyms, then get stuck. The goal of this section is clarity, not density.

Key Performance Metrics that Show up on Product Info

- U-factor (U-value): describes how quickly heat transfers through the window. Lower generally indicates less heat loss.

- SHGC (solar heat gain coefficient): indicates how much solar heat passes through. Useful for sunny exposures.

- ER (energy rating): a Canadian metric that balances factors like U-factor, SHGC, and air leakage. Higher is generally better for overall performance.

Quick Label Guide for Homeowners

| Metric | Best used for | Simple interpretation |

|---|---|---|

| U-factor | Winter heat loss and comfort near glass | Lower often means better insulation |

| SHGC | Overheating risk, sunny rooms | Lower can help reduce excess solar gain in hot periods |

| ER | Comparing overall performance in Canada | Higher generally indicates stronger combined performance |

ENERGY STAR qualification in Canada is tied to regional requirements, so product suitability can depend on your climate zone.

Practical Guidance by Room Exposure and Comfort Goals

Most homeowners do not buy windows for numbers. They buy them for outcomes: warmth, quieter rooms, fewer drafts, and a home that feels stable across seasons.

Scenario Guide for Selecting a Glazing Configuration

| Situation in the home | What to prioritize | Why it helps |

|---|---|---|

| North-facing rooms that feel cold | Stronger insulation values, often with triple pane, depending on the region | Warmer interior glass reduces cold spots and improves comfort |

| South or west exposure with strong sun | Low-E tuned for solar control plus a solid IGU | Helps manage overheating and glare without blocking all daylight |

| Condensation issues in winter | Better edge performance (spacer choice), stronger overall insulation, plus ventilation | Warmer interior glass reduces condensation risk at the surface |

| Busy street or urban noise | Multi-pane IGU, sometimeswith laminated options | Adds sound-dampening alongside thermal performance |

Installation and Frames: the Performance Layer that Gets Overlooked

Even high-performing glass can underdeliver if installation details leave air gaps or if the frame choice does not support airtightness and thermal performance. In real homes, these details often make the difference between noticeable comfort improvements and ongoing draft complaints.

Two Factors that Strongly Influence Real-World Results

-

Frame design and thermal performance

A well-designed frame reduces thermal bridging and supports the IGU over time. It also influences condensation behaviour around the perimeter. -

Installation quality and air sealing

Drafts are often caused by leakage at the installation interface, not by the glass itself. Proper shimming, insulation around the opening, and clean air sealing make a measurable difference in comfort.

Tony Wong, Project Manager : “Homeowners focus on glass first, but the install is where comfort is won or lost. A great sealed unit still needs a tight fit, proper insulation around the opening, and clean air sealing to perform the way it should.”

Common Questions Homeowners ask About Low-E and Insulated Glass

Does Low-E make glass look darker?

Most modern Low-E coatings are subtle. Some coatings can create a slight reflectivity or colour shift depending on lighting and viewing angle. If aesthetics are a priority, ask to see a sample or a local reference install.

Does Low-E prevent condensation?

Low-E can help by keeping the interior glass surface warmer, but condensation is driven by indoor humidity and temperature. Ventilation, humidity control, and edge performance all matter.

Is triple pane always necessary?

Not always. Triple pane can be a strong comfort upgrade in many Canadian regions, but the best choice depends on your climate, exposure, budget, and comfort priorities. A well-built double-pane IGU with an appropriate Low-E coating can still be a major improvement over older windows.

Questions to Ask Before You Sign

This section reduces confusion and prevents unpleasant surprises. It is also a strong SEO and conversion support block.

What to Confirm in Writing

| What to ask | What you should receive | Why it matters |

|---|---|---|

| What is the IGU configuration? | Double or triple pane, spacer type, gas fill | Defines the structural insulation layer |

| Where is the Low-E coating placed? | Coating type and placement within the IGU | Impacts comfort and solar behaviour |

| What are the performance values? | ER, U-factor, SHGC for the product | Enables apples-to-apples comparisons |

| What is included in the installation? | Scope, sealing approach, finishing, warranty | Protects real-world performance and durability |

For homeowners comparing quotes, clear written descriptions of the glass configuration and performance values help avoid surprises later. Clear documentation makes it easier to compare options and ensures the final result delivers the comfort you’re expecting.

DraftLOCK and integrated performance

Most high-performance Canadian windows are built as integrated systems: insulated glass units with Low-E coatings, paired with frames and installation practices designed for Canadian conditions. Canadian Choice Windows & Doors DraftLOCK positioning fits that integrated approach, focusing on comfort, efficiency, and long-term durability rather than isolated features.

Helen Sin, Consumer Success Manager : “Customers often think they have to choose between insulated and Low-E glass, but the best results come from how the layers work together. It’s about balancing heat retention and solar control for your home and climate.”

FAQ

Where is the Low-E coating located in a modern insulated glass unit (IGU)?

Low-E is typically applied to an interior-facing surface inside the sealed IGU, so it’s protected from weather and normal cleaning. The exact surface can vary by configuration and is chosen to balance heat retention and solar control.

Does a Low-E coating change the look of the glass (colour, reflectivity, clarity)?

Most coatings are designed to be subtle, but you may notice a slight shift in reflectivity at certain angles or lighting conditions. If aesthetics are important, ask to view a sample or a local reference installation before finalizing your quote.

What is a “warm-edge spacer,” and why does it matter?

A warm-edge spacer is part of the IGU edge system. It helps reduce heat loss at the perimeter of the glass and can improve interior-edge comfort, which may also support better condensation behaviour compared to older spacer types.

If an insulated unit fogs between panes, is that caused by Low-E?

Fogging between panes is typically a sign of seal failure in the insulated unit (moisture entering the cavity). Low-E is a coating inside the IGU, but it is not the sole driver of fogging. Seal design, manufacturing quality, and warranty coverage are key.

What should I ask for in writing to ensure I’m getting the glazing package quoted?

Request the IGU configuration (double/triple), gas fill type, spacer type, Low-E coating type/placement, and the window performance values (ER, U-factor, SHGC). Written confirmation reduces mistakes and makes quotes comparable.

Can I “upgrade to Low-E” later without replacing the window?

In most cases, Low-E is applied during manufacturing as part of a sealed IGU, so adding it later usually means replacing the sealed glass unit rather than applying a coating on-site.

What matters more than the glass package for real comfort?

Installation quality and air sealing. Even strong glazing can underperform if air leaks remain around the opening or if insulation and sealing details are rushed.

1000’s of Colours & Textured Finishes

Transform your home from ordinary to extraordinary with our new coloured and non-glare textured finishes. Available in a wide array of colours as well as custom matched colours for your very own personalized design.

Our Most Popular Replacement Window Colours: